Leather Insights

A Comprehensive Guide for Buying

the Best Leather

Buying a genuine leather item requires thoughtful consideration and keen eye of recognizing the quality of leather. For most average shoppers, leather is just leather. But, many of you know that isn’t true, right? Manufacturers often use different types of leather, depending on the end product.

As you are going to invest considerable funds for buying your favorite genuine leather products, you must know two things:

What is the best place to buy leather?

How to buy the best leather?

While making a final decision is up to you, the details provided in this leather guide has everything that will surely level up your knowledge to make the final decision.

But, before we dug deeper into various types, qualities, and features of leather, let’s first take a glimpse at the history of the leather industry and how it has developed over time.

Leather Industry

Leather tanning has been around for centuries.

It’s one of the oldest industries in human civilization. Indians, Egyptians, Greeks, Chinese, and Mesopotamians had developed several different tanning processes centuries before industrialization.

Leather was used to make intricate clothing articles such as footwear, gloves, and armor. It was also used to make buckets, bottles, and even weapons. The Industrial Revolution brought all kinds of new technological advances that made the leather-making process highly efficient, environment-friendly, and hygienic.

The leather industry in the United States dates back to the colonial times. It grew with the population throughout the 18th century. By 1750, there were more than 1000 tanneries in the country. The number swelled to more than 8000 by 1840! At the time, the primary leather activizty was shoemaking. In 1850, over 11,000 shoemaking establishments were operating in the U.S.

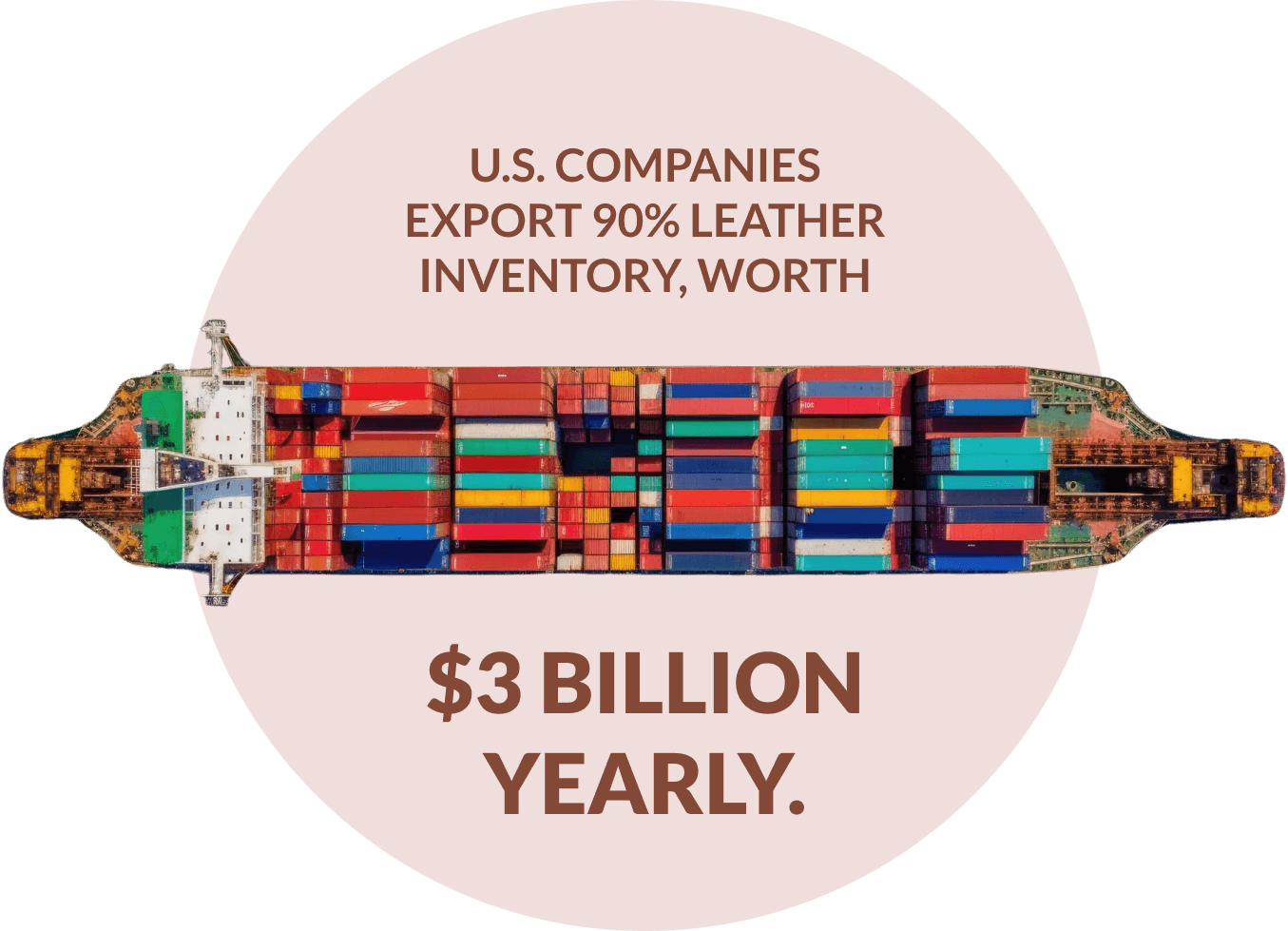

U.S. Leather Industry

U.S. hides and skins companies, which include producers, processors, brokers, and dealers, export more than 90% of the total leather inventory. The U.S is one of the top raw material suppliers to the global leather manufacturing industry. The value of industry exports is worth nearly $3 billion dollars annually.

The hide, skin, and leather industry exported more than $2 billion in cattle hides, pigskins, and semi-processed leather products.

Global Leather Goods Market

According to the report the global leather market is expected to grow at a compound annual growth rate (CAGR) of almost 4.36% from 2022-2027.

In 2017, the total market value was $217.49 billion. It is expected to reach $354.27 billion by 2027.

This segment is expected to represent an incremental growth of more than $136.78 billion during the forecast period.

The sub-segment of global footwear market was worth $129.30 billion in 2023.

On the other hand, a recent market report by Technavio claims that the global leather market will register a revenue of almost $289 billion by 2022.

Types of Leather

Mastering leather knowledge ensures longevity, value, and wise investment in your purchases.

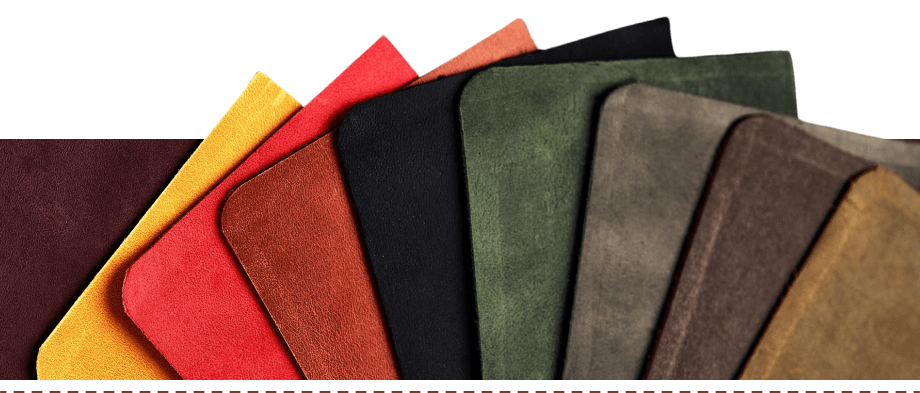

The quality of leather varies greatly. You have most likely seen different labels on leather items, such as top grain or genuine. These are simply different types of leathers based on their quality.

Now, can you get the best bang for your buck? Yes, you can.

Knowing where to buy leather is just not enough, you must learn to distinguish between different types of leather. You will need to understand why some materials last longer than others and why a particular leather bag costs thousands, while others cost a fraction of that price.

1st Grade, Best Quality

- Offers solid, close-fibered material that is water-resistant, ensuring optimal durability

- Recommended and guaranteed for superior wear

2nd Grade, Good Quality

- Provides reliable durability

3rd Grade, Fair Quality

- Features a loose fiber structure

- Susceptibility to sponging and swelling when exposed to water

4th Grade, Poor Quality

- Only good for a part of the item that is not exposed

So, what is the best leather? The best quality leather will depend on these important factors, most notably:

Different breeds of cows will produce different quality hides due to their genetics and environment. Hot climates tend to have insects that bite the animal and leave scars whereas cold climates don’t suffer from pests as much. Certain breeds might have more protective hair or thicker skins due to the weather.

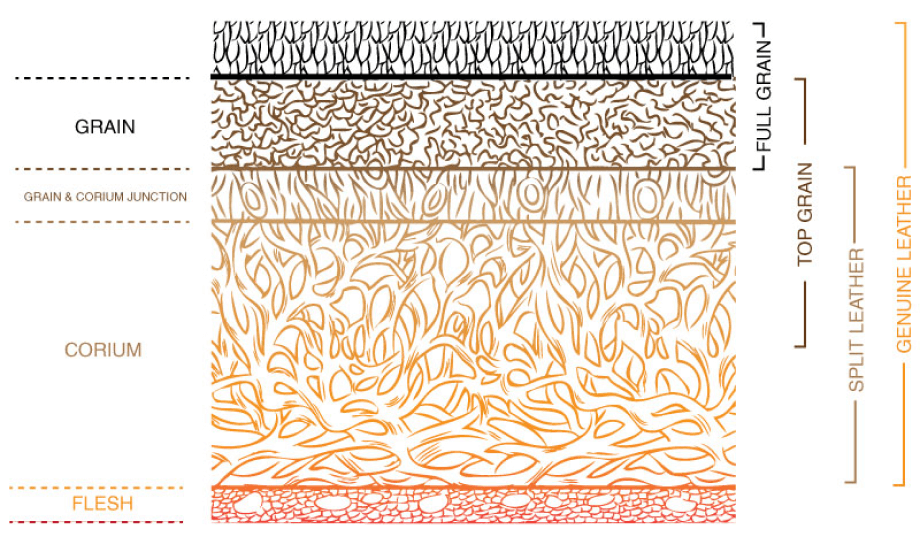

Different portions of the hide also yield different quality leather. For instance, the lower portion, as shown in the diagram above, tends to have looser fibers that make up the hide. The looser fibers sponge and swell when wet. Lower portions of the hide also tend to get marked much easier from insects and scrapes like barbed wire fencing. There are also more wrinkles in the hide around the legs, neck and head. These scars and wrinkles become permanent and are almost impossible to remove in the processing of the leather.

Different layers within the hide also have an enormous impact on quality. Full grain leather and top-grain are the best. See our in depth focus on the grain vs split just a few paragraphs further down to know which portion you are buying.

Finally, knowing exactly how to take a raw hide and process it through tanning and finishing is a sought after skill and will influence the quality of the final product significantly. Italian leather is admired for this very reason

As Italian leather artisans are considered amongst the most skilled in the world.

In general, there are four types of leather. These include Full Grain Leather, Top Grain Leather, Corrected Grain Leather, and Bonded Leather. Take a look at the picture below. See how the fibers run both horizontally and vertically in different parts of the hide.

Main Four Types Of Leather

Full Grain

Leather

Top Grain

Leather

genuine

Leather

Bonded

Leather

Buying leather with more horizontal fibers wears out quickly because they can readily pull apart. Vertically running fibers, however, are the strongest. In other words, the higher the number of vertical fibers, the better.

Full Grain Leather

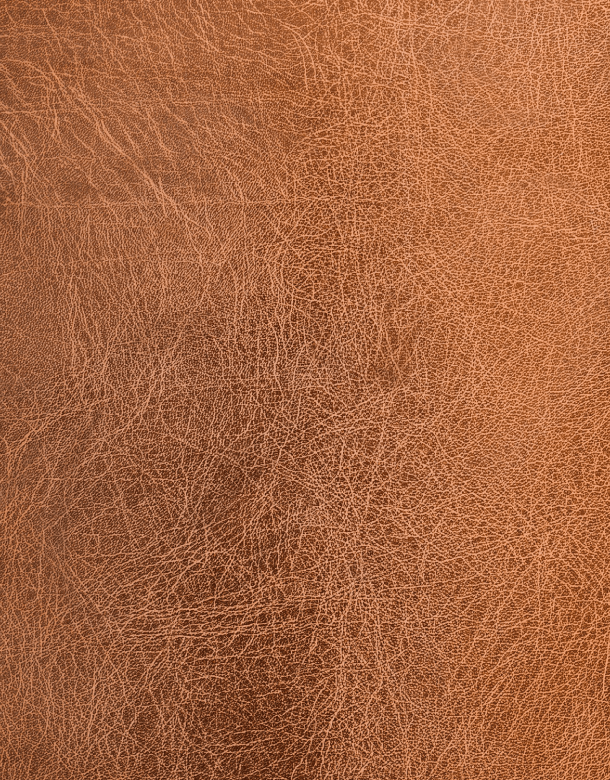

Full grain leather comes from the top layer of the hide. It includes all the grain with it – hence the name full grain leather. This type of leather retains the inherent toughness, as well as the imperfections because there are no surface alterations or splitting.

It is the highest quality leather and the only one suitable for saddleback. Thus, it is also the most expensive. Working with this leather material is challenging. It absorbs body oils and develops a patina over time – a characteristic that attributes to its popularity.

COMMON USES:

Saddlebacks, sought-after leather products.

Top Grain Leather

Top grain is the second highest grade of leather. Usually, to obtain top grain leather, the top layer of skin from blemished hides is split. The surface is sanded to get rid of inherent imperfections. Pigmentation or staining gives the leather an attractive look.

This also makes top grain leather smoother and more flexible than the full grain. Although this type of leather is strong and durable, it tends to stretch permanently over time. It is used to produce suede and nubuck. Most high-end products, such as handbags and jackets, are comprised of top grain leather.

COMMON USES:

Suede and nubuck-making, making high-end products such as handbags and jackets.

Corrected Grain (Bottom Cut/Split) Leather

Corrected grain or split leather, also known as genuine leather, is produced using the skin layers that remain after the top is split off and from the corium predominantly (see diagram above). Split leather tends to be tougher in texture due to the fact that is resides under the top layers and is mostly used in applications that don’t require the leather to be soft like furniture backs and sides. Just like the top grain leather, it is also sanded to remove natural imperfections. Usually, the surface is spray painted and embossed with a leather-like pattern to resemble natural appearance. However, the processing alters the inherent breathability of the leather.

COMMON USES:

Making jackets, handbags, messenger bags, accessories, footwear, and furniture.

Bonded Leather

Bonded leather is made up of leftovers of the hide. This includes the dust and shavings.

These are bonded together using polyurethane or latex on top of a fiber sheet. It is often spray-painted to look like full or top grain leather. You can’t determine the percentage of natural leather unless the manufacturer chooses to disclose it – which is very unlikely. Bonded leather is the lowest (and the cheapest) grade of leather.

COMMON USES:

Making furniture, bookbinding, and various fashion accessories.

Exploring the Diversity of Leather

Though there are four basic types of leather, you can find a wide range of options based on the percentage of organic material, durability, and the finishing process.

It is the most natural leather with minimal resistance to soiling. Generally, soft and tanned animal hides, such as Napa, are subject to dying in a drum with aniline dyes exclusively. Aniline dyes are translucent and water-soluble dyes that bring out the natural markings, scars, and wrinkles in the hide.

It develops a natural patina over time. As this process is suited to only high-quality animal hides, it is one of the most expensive leathers in the world. It also needs regular upkeep.

COMMON USES:

Making luxury accessories such as wallets, bags, jackets, and sought-after furniture.

Producing oil-tanned leather involves processing it with natural oils after the initial vegetable tanning is complete. Most tanneries use fish oil, particularly cod oil, for the tanning process. The purpose is to create a remarkably smooth and flexible finish. These qualities enhance its workability making oil-tanned leather more suitable for textured leather products.

The oil treatment also lends higher water and moisture resistance. It can also fend of scuff marks or minor scratches quickly, a feature all outdoor leather products must have. But most importantly, oil-tanned leather is revered for its beauty. It is available in a variety of stunning colors and finishes. It also develops a gorgeous patina over time.

COMMON USES:

Outdoor leather gear such as shoes, jackets, bags, and coats, among others.

Split leather is a single layer of leather separated from the animal hide. Usually, the middle or lower section of the hide is used to produce split leather. When it is coated with a polymer and embossed to resemble natural leather-like look, it becomes finished split leather. You can also treat this type of leather with various embossing patterns and finishing touches. Finishing is required to get a surface resembling the finished full-grain leather.

However, it is almost always used in low-stress applications as finished split leather is considerably weaker than grain leather. It is also virtually impossible for the naked eye to differentiate between full grain pigmented leather and finished split leather.

COMMON USES:

Leather accessories and furniture.

To create pigmented leather, a polymer surface coating containing pigments is applied to create the desired look and properties. It is rarely good-quality as a layer of colored polyurethane and varnish often alters the qualities of the hide.

Pigmented leather has uniform surface and color without any inherent defects of the animal skin. It is extremely durable and requires less maintenance. It also offers high resistance against scratches and stains.

Sometimes, however, over-coating can lend it plastic-like an appearance. The pigmentation also reduces its breathability. Due to its durability and low maintenance, pigmented leather is often regarded as the best leather for furniture, especially in the affordable price range.

COMMON USES:

Furniture, accessories, and car upholstery.

While preparing corrected grain pigmented leather, manufacturers subject the hides to sanding and buffing to remove imperfections such as scars and bite marks. Manufacturers often emboss the treated surface with artificial grain and sprayed with a sealer top-coat. This coating lends a more plastic feel to the leather.

The look of corrected grain leather may vary considerably, depending on the embossing and pigmentation process. There are different grades of corrected grain leather. Normally, less corrected grain means better leather quality. It is perhaps the most widely-used leather around the world.

COMMON USES:

Making jackets, handbags, messenger bags, accessories, footwear, and furniture.

Latigo is nothing but cowhide leather specifically designed for outdoor use. A combination of chrome and vegetable tanning is used to make Latigo leather. It brings out the best of both processes, resulting in leather that is durable and supple.

Some tanners may also infused it with oils and waxes through various methods such as hot-stuffing, wet-stuffing, and fat liquoring. The twofold tanning process makes it one of the most expensive leathers in the market.

It is suitable for rough usage as it has strong resistance to moisture and sweat. It can quickly turn from rigid to supple in texture. Although Burgundy is the traditional color of Latigo leather, it is now available in shades of brown, black, and red.

COMMON USES:

Riding tacks, straps, belts, pet collars, leashes, belts, saddlebacks, cinches, and army accouterments.

Chrome-tanned leather uses chromium salts (chromium sulfates) for tanning the leather instead of vegetable tannins or aldehyde chemicals. Chrome tanned leather is supple, resilient, moderately durable, and has better water resistance. You can use a variety of dyes to produce leather with several different vibrant colors.

However, chrome tanning has extremely grave environmental costs, especially in developing countries. The lack of proper recycling measures often allows the toxic wastewater to sip into the groundwater supplies and also affect the soil. Also, chrome leather is not suitable for patterning and stamping, owing to its supple nature.

COMMON USES:

Making products that don’t require stiffness or structural toughness such as jackets, bags, gloves, and upholstery.

Embossed leather is leather with artificial patterns imprinted on the natural grain of animal skin using heat and high pressure. Typically, steel plates with different engraved designs are used to create embossed leather for a variety of applications, including upholstery and accessories.

The most common types of embossing include blind embossing, gold embossing, and color imprint. While blind embossing involves imprinting patterns without any color, gold embossing includes using gold films for imprinting. Color imprint, on the other hand, uses color films for the embossment. Sometimes, the leather may also be bonded with foam and lining to allow the embossed patterns to retain their shape for longer.

COMMON USES:

Leather furniture, accessories such as bags and jackets, and upholstery.

Aniline dyed leather is typically used to produce nubuck leather, which comes from the top grain of the hide. It is sanded on the grain side to create a velvety appearance. This velvety appearance and feel often attract shoppers into buying nubuck leather products.

The buffing or sanding removes the visible markings and defects in the top grain. Staining or dying further removes the defects left after buffing. Being made from top-grain leather, nubuck is more durable compared to suede or bonded leather. However, it is susceptible to environmental factors such as mud, dirt, and grit. That’s why nubuck shoes are suited for trekking and other outdoor activities.

COMMON USES:

Shoes, jackets, wallets, handbags, travel bags, briefcases, and furniture, among other leather items.

Crust:

Crust leather is tanned and dried, but not dyed. Depending on the tanning process, it is called either chrome crust or vegetable crust. However, crust leather is not processed until it is dyed. It has all the physical properties including size, thickness, fullness, looseness of grain, and grain damages.

COMMON USES:

After finishing it can be used to make leather accessories, footwear, and furniture.

Pull-Up Leather:

Pull-up leather or oily pull-up leather stretches over time, providing a unique worn-in effect. It is considered a sign of high quality. Usually, semi-aniline animal hides are used to make this type of leather.

The waxes or oils often darken the original coloration. When stretched and pulled apart, it reveals unique light-colored variations. You can see a beautiful patina developing over time and with wear, providing an aesthetic edge to the leather product.

COMMON USES:

All leather accessories, especially the best leather for furniture.

Suede

Suede is one of the most popular leather types with a napped finish. Made from the underside of the animal hide such as lamb, goat, calf, pig, and deer, it comes with an attractive finish. As it is thinner and less durable, suede is also vulnerable to damage. It is one of the best grades of leather revered for its look and feel, not durability.

COMMON USES:

It is used to make jackets, shoes, shirts, purses, curtains, gloves, and furniture.

Pebble Grain Leather:

Pebble is a type of grain or texture of the leather. The top side of such leather mimics a pattern of small pebbles. This texture can be both, natural and artificially embossed. However, natural pebble pattern is not consistent. It is one of the distinguishing features between natural and artificial pebbles. You can find it in almost all types of leather, ranging from full-grain premium hides to lower-grade skins.

COMMON USES:

Almost all leather products across all price ranges, including accessories and furniture.

Kidskin Leather

Kidskin leather comes from the hide of lambs or young goats. It is flexible, durable, and supple. It is also extremely lightweight. However, being high-quality leather, it is also one of the most expensive grades of leather. It is less costly than calfskin and requires high maintenance.

COMMON USES:

Primarily to make gloves for women, kids, and men.

Antique Grain Leather

Also called as distressed leather, it is a type of leather treated to get the rugged appearance of antique or vintage leather. More often than not, the leather surface gets applied with an uneven or partially rubbed-off contrasting top-coat revealing a pale underlying color. This weathered look often tends to attract most shoppers, especially when shopping for leather accessories and furniture.

COMMON USES:

Making accessories such as wallets, bags, belts, and jackets.

Printed Leather:

Printed leather is often stamped with a design or texture to create a unique look. From genuine Italian leather to lower-grade hides, you can find printed leather in almost all price ranges.

Manufacturers often use screen printing or inkjet printing process to imprint patterns, symbols, and ornaments on the leather. In recent years, advancements in the development of leather printing ink have made it possible to print beautiful, intricate, and multi-colored patterns.

COMMON USES:

Book covers, bags, jackets, and even furniture.

Chrome-Free Leather:

Chrome-free leather is made from alternative tanning processes such as vegetable tanning or aldehyde tanning. The environmental pollution resulting from the chrome-based tanning process has compelled many governments and tanneries to adopt these chrome-free tanning processes. The processed leather has almost all the chrome-tanned leather qualities such as higher shrink resistance, more resilience, and flexural strength. Further, there are no toxic effluents degrading the environment.

COMMON USES:

Making infant shoes and automobile accessories.

Waxy Hand Leather

Waxy hand leather comes with a grease or wax finish. The soft and scratch-sensitive leather surface develops a beautiful patina over time upon folding, scratching and stretching.

COMMON USES:

Upholstery, shoes, handbags, and different types of leather furniture.

Tooling Calf Leather

Tooling calf is thin and lightweight vegetable-tanned leather. As the surface is unfinished, it is suitable for leatherwork such as printing, stamping, carving, and engraving. It has a more buttery and supple texture.

COMMON USES:

Insides, interiors, and linings.

Saffiano Leather

Wax finished leather with a cross hatch texture created by a machine. Usually made from calfskin.

Patent Leather

Leather coated with a lacquer, usually plastic, to give a slick, mirror-like finish.

Nappa Leather

“Nappa” is a generic name for soft, dyed leather usually used in advertising. There is no distinct test to characterize nappa leather.

Good Hand Leather

It is highly soft leather. As it feels good against the skin, it is known as good hand leather.

Skirting Leather:

Skirting leather is made from the sides of cattle hide. Heavyweight, full-thickness skirting leather offers exceptional strength, making it ideal for making saddles and bridles. Skirting leather is prized for its beauty, workability, and affordable cost of the end-product.

COMMON USES:

Often used to manufacture saddles and bridles.

Semi-Aniline Leather

Semi-aniline leather consists of a light surface coating with a small amount of pigment. Thus, it is stronger than aniline leather but maintains its natural look. It also exhibits stain resistance to some extent.

Leather Thickness

Thinner Hides

The leather thickness and weight play a critical role in deciding what the end product will be. For example, thinner hides (1-3 ounce) are used to make the leather jacket, furniture, moldings, linens, and embossing.

Thick hides

Thick leather, on the other hand, is often used to make items such as leather belt, knife sheaths, holsters, saddlebags, and leather dog collar.

The ounce is the standard unit of measuring the leather thickness. However, some leather thickness charts may also use millimeter and inch as the measuring unit. Typically, an ounce of leather equals 1/64 of an inch. However, the leather thickness varies slightly as the hide doesn’t have a uniform thickness. Split leather may have a more consistent thickness than a rawhide. But, you will still find some variation.

You change, of course, vary the thickness as per your personal taste. Staying within the recommended thickness will provide increased durability. You can use the following leather thickness chart as a thickness guide for all forms of general uses of leather.

| Ounce | MM | Inch | Decimal | Used for |

| 1 | 0.40 | 1/64” | .015625 | Furniture, moldings, linens, Embossing, Jackets |

| 2 | 0.80 | 1/32” | .03125 | Furniture, moldings, linens, Embossing, Jackets |

| 3 | 1.20 | 3/64” | .046875 | Furniture, moldings, linens, Embossing, Jackets |

| 4 | 1.60 | 1/16” | .0625 | Embossing, Billfold backs, Clutches |

| 5 | 2.00 | 5/64” | .078125 | Billfold backs, Masks, Cluches |

| 6 | 2.40 | 3/32” | .09375 | Small cases, Notebook covers |

| 7 | 2.80 | 7/64” | .109373 | Carved handbags, Camera cases, Journal covers |

| 8 | 3.20 | 1/8” | .125 | Narrow belts, Knife sheaths, Small holsters |

| 9 | 3.60 | 9/64” | .140625 | Belts, Holsters, Saddle bags |

| 10 | 4.00 | 5/32” | .15625 | Heavier holsters, Wider belts |

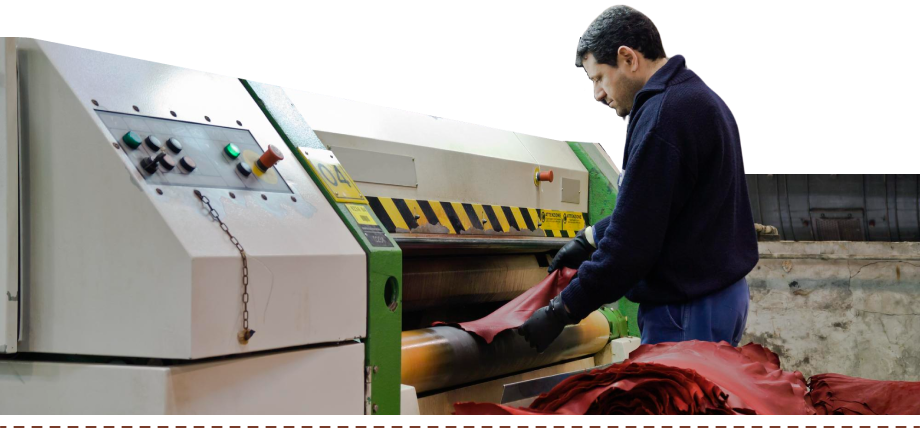

How Leather Is Made

Leather tanning is a complex and lengthy process. Though mechanization has made it less labor intensive, it still consists of a complex series of treatments that require considerable time and energy. The purpose of the tanning process is to alter the protein structure of the skin to increase its durability, texture, and appearance.

As mentioned earlier, there are many varieties of leather. However, all types of leathers have to go through four fundamental stages. This includes preparatory steps, tanning, re-tanning, and finishing. Sometimes, a further sub-process of surface coating may be added to the process. Before sending to the tannery, the animal skin needs to be cured. Although curing is not considered a part of the tanning process, it is the first crucial step in obtaining leather.

Usually, the animal is killed and skinned before the body heat leaves the tissues. The freshly removed skin or hide is immediately cured with salt to remove water. The skin is allowed to remain in the shade until it is completely dry. The cured skin or animal hide is then transported to the tanneries for further processing.

Preparatory Steps

The cured skin or animal hide needs to be prepared for the tanning process.

Although there are various preparatory processes, the purpose of each process is to remove unwanted raw skin components. The tannery may not perform all of them, depending on the quality and type of the desired product.

1.

At this stage, the cured hide is soaked in water for several hours to several days. This process not only restores the moisture lost during salting, but helps to remove dirt, debris, blood, and excess animal fats.

2.

This process removes subcutaneous material from the flesh side. The pelt is passed through a machine to remove the fat, muscle, and flesh mechanically. Usually, this process takes place after slaughter, soaking, or liming. At this stage, or after tanning, hides may be split into different layers.

3.

Hair is removed at this stage using mechanical instruments such as rollers and blades.

4.

This process involves cleaning and soaking the rawhide in acids or salts to prevent decomposition. It helps the penetration of tanning agents such as chromium and aldehydes. Stronger pickling agents are used to preserve hides for several months.

5.

The hide is soaked in sulfuric acid to lower the pH after pickling.

6.

This process loosens the fibers and allows the skin to absorb various tanning chemicals. Usually, sodium sulfide and hydrated lime are used to treat the hide, as they remove keratinous material such as hair and wool. Fats get hydrolyzed as the pH increases. Water is absorbed into the skin fibers, resulting in a swollen skin structure.

7.

In this process, the hide is washed with a mixture of water and ammonium chloride or ammonium sulfate. This removes water (along with any impurities) to reduce swelling.

8.

Bating marks the end of the liming process. The flaccid skin is treated with proteolytic bating enzymes to remove non-fibrous proteins. It cleans the grain and makes the pelt smooth and silky.

9.

Sometimes, water-based solutions and solvents are used to remove excess grease or natural fatty acids from the skin.

10.

Chemical agents are used to making the hide colorless to add the desired color at a later stage.

Tanning

The primary purpose of this process is to produce a non-decomposable and sturdy material from the raw animal hide, called leather.

Essentially, tanning converts the protein of the rawhide into a durable material. The most common tanning processes include mineral tanning, vegetable tanning, and glutaraldehyde tanning.

1.

Vegetable tanning has been around for thousands of years. Unlike mineral tanning, it uses a naturally occurring polyphenol astringent chemical called tannin. This is usually found in bark, leaves, and branches of trees such as oak, chestnut, or mimosa. As it produces shades of deep brown, beige, yellow, and red, tannin lends a unique color and texture to the leather.

However, the process is time-consuming, laborious, and expensive. There are two types of vegetable tanning processes. The slow process takes about 30 days, while the rapid tanning process only lasts about 36 to 48 hours. Sometimes, however, the slow process can take several months, as it may require multiple treatments.

This process produces highly durable leather. So, the vegetable tanned leather is often used to make products such as saddles or holsters. The unmatched durability and distinct appearance makes this leather suitable for imprinting and intricate leatherwork such as tooling.

2.

Mineral or chrome tanning is the most popular tanning process because it’s much quicker, affordable, and less labor intensive than the others. In 1858, it was introduced as an alternative to the expensive and time-consuming vegetable tanning process. The process can be automated and lasts a day at most. Usually, the time for chromium tanning is around 2 or 3 hours for small and thin skins. However, it can go up to 24 hours for thicker ones obtained from cattle.

The size of chrome molecules is small compared to vegetable tannin ions. As a result, chrome ions can penetrate the collagen and remove water molecules effectively. That’s why chrome tanned leather is thinner and softer than vegetable tanned leather. Chromium (III) sulfate is the most efficient and effective tanning agent. Chrome tanned leather is also called wet blue leather due to its bluish color.

However, the chrome tanning process creates a negative environmental impact as it comprises heavy usage of acids and other chemicals. The toxic waste can seep into groundwater and contaminate drinking water supplies. The resulting environmental implications are a major concern, especially in developing countries.

3.

This tanning process uses glutaraldehyde or oxazolidine compounds. It is also called wet white leather due to its pale cream color. Aldehyde tanned leather is water absorbent, soft, and can be machine washed. It is, therefore, perfect for use in chamois.

4.

Sometimes, emulsified oils are blended with aldehyde chemicals to produce exceptionally soft and flexible leather. This process is called oil tanning.

Re-Tanning

Re-tanning converts the tanned leather into a marketable product.

The choice of chemicals used in this process depends on the desired color and texture in the final product.

1.

At this stage, the tanned leather is pressed between two rolling cylinders to remove the water absorbed during the tanning process.

2.

This process removes flesh residues and creates uniformly thick leather. The leather passes through two rolling cylinders where the upper one is provided with helical blades.

3.

A splitting machine slices the thick leather into one or more horizontal layers. Sometimes, this process is also carried out after liming. The top grain layer is the most expensive leather. It is used to make high-end leather merchandise. The layer without grain is used to make suede leather. Sometimes, an artificial grain surface can also be applied to it.

4.

With the exception of vegetable tanned leather, all types of leather are dyed. More often than not, water-soluble dyes are used, allowing the dye molecules to penetrate inside the fibers. Thus, it differs significantly from surface coating where dye is applied only on the top layer.

5.

Fat liquoring, or stuffing, consists of adding fats, oils, or waxes between fibers to keep the leather soft and flexible. Without this process, the leather will dry and become stiff.

Finishing

This is the final stage where finishing touches are added to the tanned leather – as per the desired end product. This includes color, texture, thickness, and surface patterns.

1.

A velvet wheel rubs the leather to create a shiny surface.

2.

The process of embossing obtains a three-dimensional print using heated hydraulic or roller presses.

3.

The surface coating process adds color and different designs to leather. As per the customer requirement, resins, pigments, and dyes are added in layers to the surface using a variety of techniques such as spraying, roller-coating, curtain-coating, or hand coating.

4.

Finally, the leather is graded before it is dispatched to the customers. Grading is often based on a variety of factors such as the feel of the leather, color, pattern, thickness, softness, and flexibility.

Leather For Furniture

One of the most popular leather item categories is furniture. High-quality leather furniture can last for years. However, each type comes with unique characteristics

In other words, you need to choose the right type of leather to get the most out of your furniture. Hopefully, this quick leather furniture buying guide will help you.

As mentioned before, this is the most expensive and high-end leather out there. It is also the best for furniture because it retains a natural look and texture.

The leather is treated with transparent aniline dyes to keep the original look. The texture is a little rough in the beginning but softens over time. However, this type of leather furniture requires a lot of maintenance, as it is susceptible to sunlight and absorbs liquids readily.

Top grain leather is also suitable for furniture. This type of leather is softer than the full grain leather and comes with the same durability. Top-grain leather furniture comes in two different categories: aniline and semi-aniline. While aniline leather recliners may look natural, they remain susceptible to stains. Semi-aniline leather furniture, on the other hand, is relatively less susceptible because it can be treated with a protective topcoat.

This type of leather furniture is also expensive. At Octane Seating, we primarily use top grain leather on all portions of the seating that you will touch. This means the seat back, seat cushion, armrests, and footrest – all utilize top grain. We then use a perfect synthetic PU match (see below) on the exterior sides and the exterior seat back. The synthetic match on those portions of the seat is an excellent choice given that those are the portions that will get scratches, dirt, and nicks. The synthetic cover is easy to clean and maintain in areas like that on the furniture.

Split grain, 100% leather, lacks smooth texture and stylish appearances, challenging to maintain for furniture.

Some people may not think of it as the best leather for furniture, as it is relatively difficult to maintain.

Bonded leather is the most sought-after leather for furniture because it offers the look and texture of leather for the cheapest price.

Usually, it only consists of about 17% leather obtained from various scraps rolled up together using an adhesive material. Unlike the full grain leather furniture, it will never become smooth with age.

People tend to confuse nubuck leather with suede because they both have a velvet-like surface. However, unlike suede (obtained from split leather), nubuck is produced from the full grain leather.

This type of leather is lightly brushed or abraded to create a velvet-like plush nap. It is considered the best leather for furniture due to its soft, velvet-like touch and natural look. Though it is more durable compared to suede, nubuck leather furniture requires high maintenance, especially the velvety fur.

You should avoid buying nubuck leather furniture if you have pets.

Bi-cast leather is manufactured by blending split-hide leather or composite leather substrate and a coating of colored polyurethane. Thus, it looks like top grain leather, only it is a lot cheaper.

Just like bonded leather furniture, it also lacks the wear or comfort attributes of top-grain leather.

It doesn’t have the durability people often associate with top grain leather furniture, either. So, before buying bi-cast leather furniture, make sure you understand the pros and cons related to it.

Faux leather is a great choice for furniture upholstery, especially if you are an animal lover.

Though it is no match for high-end full grain leather furniture, faux leather furniture is durable and can last longer.

It is also affordable, less prone to cracks and peels, can withstand scratches, is not susceptible to sunlight, and is stain resistant. Thus, it can be an economical and low maintenance alternative to natural leather.

Leather Alternatives

One of the most popular leather item categories is furniture. High-quality leather furniture can last for years. However, each type comes with unique characteristics. In other words, you need to choose the right type of leather to get the most out of your furniture. Hopefully, this quick leather furniture buying guide will help you.

Polyurethane (PU) vs Polyvinylchloride (PVC) Furniture

When it comes to buying leather furniture, people often use the terms polyurethane (PU) and polyvinyl chloride (PVC) leather interchangeably. However, they are distinctly different. You must understand this difference if you want to get the best bang for your buck while purchasing leather furniture.

1) Polyurethane (PU) Leather

- Polyurethane leather is composed of polyurethane, bicast, or ground leather. Thus, it closely resembles natural leather.

- It provides a soft and flexible seating surface.

- It offers better breathability (vapor transmission), compared to PVC leather.

- The high-performance PU leather can quickly adjust to body temperature. It can remain cool even after sitting for long periods of time.

- However, it is susceptible to direct sunlight and humidity. Prolonged exposure can make it brittle.

- It comes with high abrasion resistance, durability, and inherent stain resistance.

- It is not naturally flame resistant. But, resistants are often added during the manufacturing process.

- Though it is more economical than natural leather, polyurethane upholstery tends to be expensive compared to PVC leather furniture.

PU and PVC leathers are also known as faux leather and as they are not made from animal products, they can also be called vegan leather.

2) Polyvinylchloride (PVC) Leather

- Though polyvinylchloride (PVC) resembles the softness, color, and texture of natural leather, it doesn’t contain natural leather at all.

- It is very durable and inherently flame resistant.

- It has a relatively better resistance to cleaners and disinfectants, compared to PU leather.

- Affordability and an excellent variety of color, texture, and grain are the primary reasons why this leather is the most popular one out there.

Sustainable Vegan Alternatives

There have been great innovations in the creation of environmentally-friendly, sustainable leather alternatives. One of these innovations is the invention of a leather-like material created from cactus plants. Because of its plant-based origin, this material is vegan, can be regrown quickly, and is biodegradable. The finished material offers a softness similar to real leather and can last for at least 10 years. It may not have the longevity of real leather but its an exciting discovery for those looking for quality leather alternatives.

How to Identify Genuine Leather

Buying leather can be a challenging task. There are not only different types of leather but also different types of synthetic leather. Manufactures and leather shop owners are finding new ways to sell synthetic leather disguised as genuine. Fortunately, there are a few simple tips on how to buy genuine leather.

01

Check the Label First

The first thing you should do before trying any of the following tricks is to check the label. Most high-end leather product manufacturers will proudly give you information about the type of leather they have used to make the merchandise.

Most leather products have labels indicating different types, such as ‘genuine leather’ or ‘full grain leather.’ If you see dubious labels such as ‘manmade material’ or ‘made with animal products’, chances are, it’s not genuine leather. Avoid buying leather furniture or accessories without any tags. It’s a sure shot sign the manufacturer is trying to conceal the authenticity of leather.

02

Feel the Texture

Just run your fingers over the leather to feel its texture. As genuine leather comes from animal hide, it will have a varying or uneven texture. If the surface grain feels extra smooth, chances are, it is faux leather.

03

Look for Imperfections

Genuine leather exhibits an inconsistent surface pattern having minor imperfections.

In other words, scratches, creases, and wrinkles are an indication of genuine leather

04

Warmth

Remember, genuine leather comes from hiding, which at some point, belonged to a living animal. That’s why genuine leather begets a cozy and warm feeling to your touch. Faux leather, however, feels cold and lifeless.

05

Elasticity

Just like any animal skin, genuine leather changes color when stretched and has better elasticity. If you press your finger firmly against natural leather, it will wrinkle under pressure. But, it will regain the original quickly. Faux leather, however, will retain the shape of your finger for a while.

06

Smell

Real leather has a distinct leathery smell. It retains the smell even after going through the tanning process. The synthetic leather material, on the other hand, smells like plastic.

07

Rough Edges

Whether you are out shopping for leather recliners or handbags, they will always have rough or coarse edges. As genuine leather is made of several layers, the edges often fray over time. Faux leather products, however, have smooth edges.

08

Moisture

Unlike its synthetic counterparts, natural leather readily absorbs moisture. Splash a drop of water on your leather merchandise. If it soaks up the water in seconds, chances are it’s a genuine leather item.

09

Fire Test

You have to execute this test carefully, as it will damage a part of your leather accessory. You can do this test on a hard-to-see area, such as the underside of your leather recliners. Burn the designated area using a matchstick. Genuine leather will slightly char and produce a distinct smell of burnt hair, while faux leather smells of burning plastic.

10

Check the Cost

Irrespective of how hard you bargain, genuine leather will always be expensive. When it comes to leather shopping, there are no cheap deals.

11

Understand Different Types of Leather

The more you know about leather, the better. So, try to understand as much you can about the different types. When in doubt, refer to this guide.

Wrapping It Up

Even the smallest things made of genuine leather are quite expensive. So, you have to put a lot of thought into buying leather products, big or small. The cost, quality, and aesthetics of leather depending on various aspects including the type of animal hide, tanning process, and finishing touches. Hopefully, this guide will address all your concerns from understanding leather grades and manufacturing processes to identifying and buying genuine leather. How about you? Have you purchased leather furniture or accessories recently? Share your experience in the comments section below.

What type of leather is the best?

The best type of leather depends on personal preference and the intended use. Some of the most highly regarded types of leather include full-grain leather, which is the most durable and retains the natural markings and character of the hide; top-grain leather, which is slightly sanded and treated for a more uniform appearance; and genuine leather, which is made from the layers of the hide, but is often treated and finished to enhance its appearance. Ultimately, the best type of leather is the one that meets the individual’s needs in terms of aesthetics, durability, and intended use.

Which is the best leather for furniture and upholstery?

The best leather for furniture and upholstery depends on personal preferences and specific needs. However, full-grain leather is often considered the highest quality and most durable option. It is made from the entire thickness of the hide and retains the natural character and imperfections, giving it a unique and luxurious appeal. Other types of leather, such as top-grain and corrected-grain, can also be suitable choices, depending on factors such as price, desired appearance, and usage requirements. It is recommended to consult with professionals or do thorough research to determine the best leather option for your specific furniture and upholstery needs.

What is the best type of leather for shoes and footwear?

The best type of leather for shoes and footwear varies depending on personal preferences and requirements. However, full-grain leather is often considered the highest quality and most durable option. It is made from the top layer of the hide and retains the natural texture and imperfections, giving it a unique and luxurious appearance. Other types of leather, such as top-grain and genuine leather, may also be suitable depending on factors like desired stiffness, flexibility, and cost. Ultimately, it is important to consider factors like comfort, durability, and aesthetics when choosing the best type of leather for shoes and footwear.

What kind of leather is recommended for clothing and garments?

The type of leather recommended for clothing and garments is typically lambskin or sheepskin, as they are softer and more flexible compared to other types of leather. These types of leather provide a comfortable fit and drape well on the body, making them ideal for fashion garments. Additionally, lambskin and sheepskin have natural insulating properties, making them suitable for various weather conditions.

What's the best leather for belts and saddlery?

The best leather for belts and saddlery is usually full-grain leather. Full-grain leather is the highest-quality leather available as it retains the natural grain and characteristics of the hide. It is extremely durable, has a beautiful appearance, and develops a unique patina over time. Additionally, full-grain leather has excellent strength and resistance to wear, making it an ideal choice for products like belts and saddlery that require durability and longevity.

What animal does most leather come from?

Most leather comes from cattle.

What leather doesn't crack?

Several types of leather are less prone to cracking, such as full-grain leather, top-grain leather, and vegetable-tanned leather. These types of leather are generally more durable and resilient, making them less likely to develop cracks over time. However, it is important to note that proper care and maintenance, including regular cleaning and conditioning, are crucial in preventing any leather from cracking.

How can you tell what is real leather?

- Real leather will have a distinctive smell, often described as a natural or earthy scent.

- Genuine leather will feel smooth and soft to the touch.

- Look for inconsistencies in grain patterns and natural imperfections, as real leather will often have these unique characteristics.

- Real leather is more expensive than imitation leather, so consider the price point and quality when determining its authenticity.

- Full grain leather: This is the highest quality leather, made from the top layer of the hide, providing exceptional durability and a natural look.

- Top grain leather: This is the second highest grade, where the top layer is sanded and finished for a smooth and uniform appearance while still maintaining some natural characteristics.

- Corrected grain leather: This grade of leather undergoes additional treatment to remove imperfections, and an artificial grain pattern is applied to create a more uniform look.

- Bonded leather: This is made from leftover leather scraps that are bonded together with adhesive, resulting in a lower-quality, synthetic-like material.

What is the softest leather?

The softest leather typically comes from the hides of young animals, particularly lambskin or calfskin. These hides have a smoother texture and less fibrous structure, making them feel incredibly soft and supple to the touch.

What is poor-quality leather?

- Poor-quality leather is made from low-grade animal hides that have been poorly processed.

- It may have visible flaws, such as scars, blemishes, or discoloration.

- It is less durable and prone to cracking, peeling, or tearing over time.

- Poor-quality leather may have an unpleasant odor and lacks the softness and smoothness of higher-quality leathers.

What is the most expensive leather?

The most expensive leather is typically considered to be genuine alligator or crocodile leather. These exotic leathers are highly prized for their unique texture, durability, and rarity. However, other luxury leathers such as ostrich, python, and shark can also command high prices depending on their quality and availability.

Where does the best leather in the world come from?

The best leather in the world often comes from countries known for their longstanding expertise in leather production, such as Italy, France, and England. These countries have a rich tradition of skilled artisans and tanneries that have perfected the art of leather making over generations. Additionally, the quality of leather is often influenced by factors such as the breed and environment of the animals, as well as the tanning process used.

Is 100% leather made from animals?

Yes, 100% leather is made from animals. Leather is a material that is derived from the skin of animals such as cows, sheep, or goats. The process involves treating and tanning the animal hides to create a durable and versatile material often used in the fashion and furniture industries.

What is nubuck leather?

Nubuck leather is a type of leather that has been sanded or buffed on the grain side, resulting in a velvety or suede-like texture. It is durable and soft to the touch, making it a popular choice for footwear, clothing, and accessories. Nubuck leather is often confused with suede, but they are slightly different in terms of the manufacturing process and texture. Overall, nubuck leather is known for its luxurious appearance and feel.

What is Nappa leather?

Nappa leather is a luxurious, soft, and supple leather made from the hide of lambs or sheep. It is known for its smooth texture, durability, and versatility. Nappa leather is commonly used in high-end fashion items such as handbags, wallets, shoes, and upholstery due to its high quality and refined appearance. It is highly prized for its ability to age beautifully and develop a unique patina over time.

What is full-grain leather?

Full-grain leather is the highest quality and most durable type of leather available. It is made from the top layer of the hide, which is the strongest and most dense part of the animal’s skin. This type of leather retains the natural grain and imperfections of the hide, giving it a unique and authentic appearance. Full-grain leather is highly sought after for its natural beauty, superior strength, and ability to develop a desirable patina over time. It is often used in high-end leather products such as luxury bags, belts, and footwear due to its exceptional quality and longevity.

Can you wash leather?

Yes, you can wash leather, but it is important to follow proper care instructions and use the appropriate cleaning products. It is recommended to use a mild soap or leather cleaner and a soft cloth or sponge to clean the leather gently. Avoid using excessive water or soaking the leather, as it can damage the material. After cleaning, it is important to let the leather air dry naturally and avoid using heat sources, as they can cause the leather to become stiff or crack. Additionally, it is important to condition the leather regularly to keep it moisturized and prevent it from drying out.

Is patent leather real leather?

No, patent leather is not real leather. It is a type of coated leather that has been treated with a glossy finish, typically made from synthetic materials such as polyurethane or PVC. The coating gives patent leather its distinctive shiny appearance.

Does leather shrink?

Leather is not known to shrink under normal circumstances. However, if leather is exposed to excessive heat or moisture, it may undergo some changes in size and texture. It is important to care for leather products properly and avoid exposing them to extreme conditions to maintain their original size and shape.

Does leather stretch?

Yes, leather can stretch. It may stretch over time with use and conform to the shape of the wearer’s body.

Does real leather peel?

Real leather does not typically peel. However, if the leather is of low quality or has undergone poor treatment processes, it may start to peel or crack over time. Proper care and maintenance can help prevent peeling of real leather.