Types of Wood

Guide to Choose the Best for Your Furniture

Different types of wood for furniture (both hardwood and softwood) are available in the market. Each type comes with a different set of characteristics in terms of color, density, grain, and finishing. Picking the right wood for furniture is critical as it helps you to determine the exact price of your unit. It will also be a deciding factor when you want to restore, resale, or discard a piece of furniture.

Although you can use any type of wood to make furniture, not all woods are made equal. That’s why you need to choose it carefully.

When it comes to choosing the best wood for your furniture, understanding its properties is a must. This guide will provide you with detailed information on the various aspects of wood including :

But before we go into the details, let’s take a look at some of the latest and most relevant stats.

In 2018, the total area of timberland in the United States amounted to some 514 million acres.

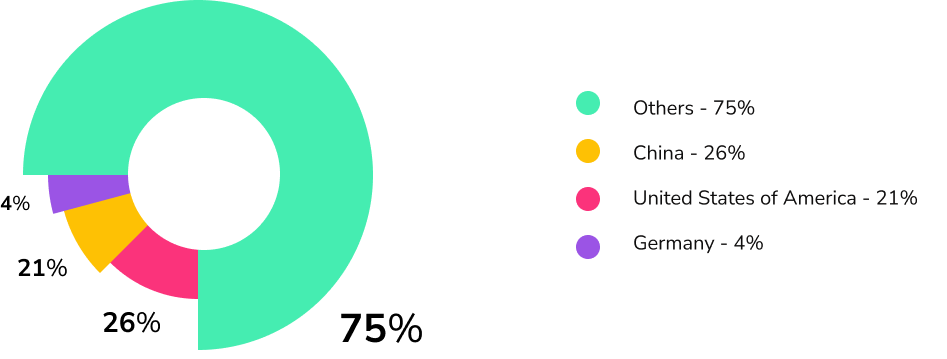

China (26%) was the highest consumer of sawn wood in 2017, followed by the United States of America (21%) and Germany (4%).

The U.S market for furniture is expected to grow at a compound annual rate of 2.9% through 2019.

Rank

Exporter

2017 sawn wood export

1.

Canada

US$8.3 billion (22% of exported sawn wood)

2.

Russia

$4 billion (10.3%)

3.

United States

$3.8 billion (9.8%)

4.

Sweden

$3.1 billion (7.9%)

5.

Germany

$2.14 billion (5.5%)

6.

FInland

$2.05 billion (5.3%)

7.

Thailand

$1.5 billion (3.9%)

8.

Austria

$1.47 billion (3.8%)

9.

Malaysia

$900.2 million (2.3%)

10.

Chile

$803.2 million (2.1%)

11.

Latvia

$684.2 million (1.8%)

12.

Brazil

$665.3 million (1.7%)

13.

New Zealand

$613.9 million (1.6%)

14.

Blegium

$568.4 million (1.5%)

15.

Romania

$527 million (1.4%)

On the other hand, the global furniture market was valued at around $331.21 billion in 2017. It is expected to reach approximately $472.30 billion by 2024, growing at a CAGR of around 5.2% between 2018 and 2024.

Types of Wood

(The Wood Database)

Hardness is one of the simplest ways to distinguish the wood used for furniture. Contrary to the popular belief, hardwood is not necessarily harder and denser compared to softwood. In botanical terms, hardwood comes from flowering trees while softwood comes from conifers. Both hardwood and softwood are used for everything from structural to decorative purposes.

Hardwood

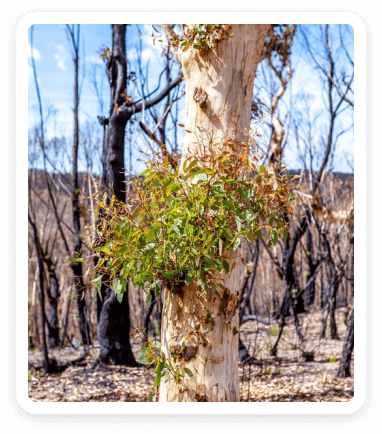

Hardwood comes from Angiosperms such as maple, oak, and walnut. These trees lose their leaves annually (deciduous or broad-leafed trees). As they grow slowly, hardwood has denser wood fibers (fiber tracheids and libriform fibers).

An interesting fact about hardwood is that some types of hardwood can’t float in water. For example, Black ironwood is perhaps the hardest and heaviest wood that sinks in water.

Properties of Hardwood

It grows slowly compared to softwoods. So, hardwood is relatively expensive. However, there are exceptions. For example,

Gum is a hardwood that comes at a price comparable with most types of softwood.

Hardwood is durable. (less likely to decay and rot), comes with close grain, and requires low maintenance.

As it comes with low sap content and good fire resistance, hardwood is commonly used for wooden flooring. However,

hardwood flooring is also revered for its varied natural colors, styles, and perforation plate patterns.

It is also used for making furniture.

However, not all types of hardwood are ideal for making furniture.

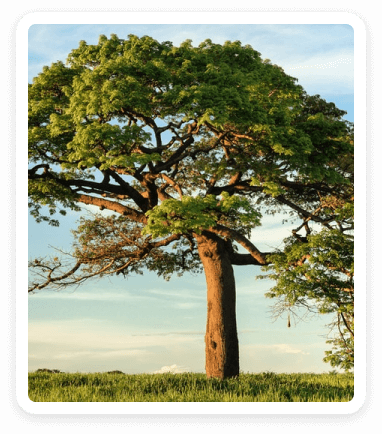

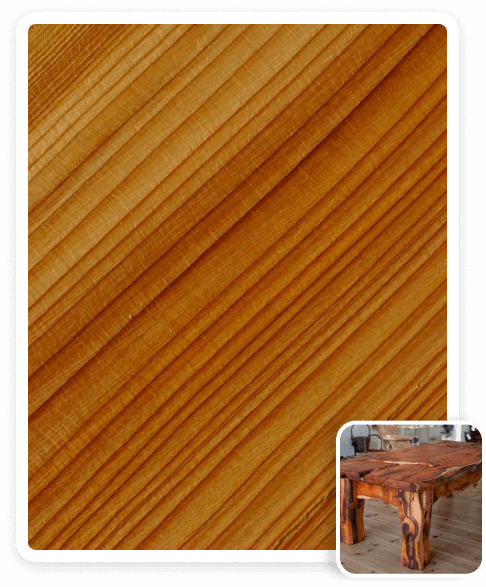

Softwood

Softwood comes from gymnosperms, which are seed-bearing evergreen trees such as pine, spruce, fir, cedar, juniper, redwood, and yew. As most evergreen trees tend to be less dense than deciduous trees, it is easier to cut them down. They also grow tall and straight, making it easier to cut long straight planks of wood.

Properties of Hardwood

Usually, softwood consists of tracheids and wood rays but lacks vessels.

As vessels are absent, softwood is also called non-porous wood.

The lack of vessels allows softwoods to absorb adhesives quickly, resulting in a better finish.

Softwood is commonly used in building material such as structural frames, exterior and interior wall cladding, fittings, floor coverings, formwork, and scaffolding, among others.

It is also used in the paper and cardboard industry.

It comes with loose grain, higher sap content, and lighter color.

However, it has poor fire resistance.

Its fine and lightweight structure makes it the best wood for furniture.

Hardwood vs Softwood: The difference

No

Hardwood

Softwood

1.

Hardwood comes from angiosperm, deciduous trees.

Softwood comes from coniferous, evergreen trees.

2.

It comes with rough wood texture.

It comes with fine wood texture.

3.

The presence of vessels makes it porous

The absence of vessels makes it non-porous.

4.

Tracheid content is around just 5% to 10%.

Tracheid content is around 90% to 95%.

5.

The complex anatomical structure makes hardwood denser.

The relatively less complex anatomical structure makes softwood less dense.

6.

Not all types of hardwood are ideal for furniture making. Being expensive, they are usually used in high-end furniture manufacturing.

Almost all types of softwood are ideal for furniture making. In fact, about 80% of all timber comes from softwood.

Hardwood

1. Hardwood comes from angiosperm, deciduous trees.

2. It comes with rough wood texture.

3. The presence of vessels makes it porous

4. Tracheid content is around just 5% to 10%.

5. The complex anatomical structure makes hardwood denser.

6. Not all types of hardwood are ideal for furniture making. Being expensive, they are usually used in high-end furniture manufacturing.

Softwood

1. Softwood comes from coniferous, evergreen trees.

2. It comes with fine wood texture.

3. The absence of vessels makes it non-porous.

4. Tracheid content is around 90% to 95%.

5. The relatively less complex anatomical structure makes softwood less dense.

6. Almost all types of softwood are ideal for furniture making. In fact, about 80% of all timber comes from softwood.

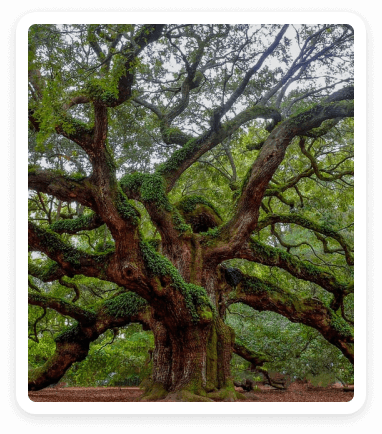

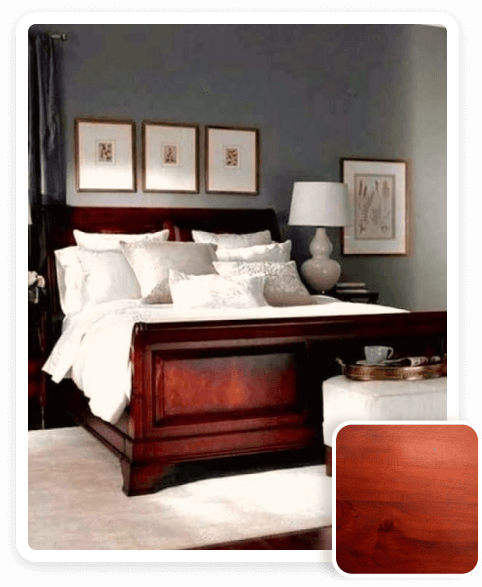

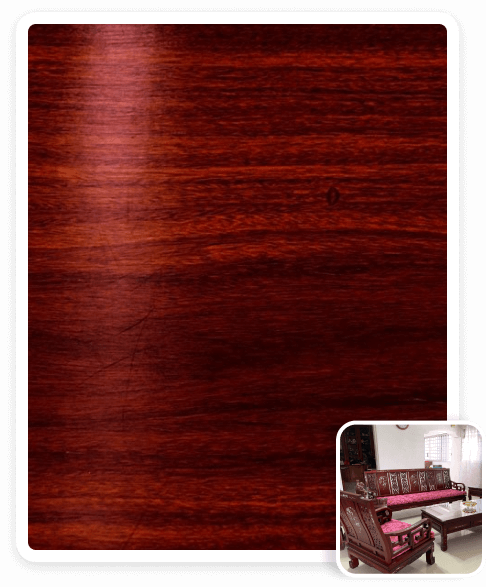

Red Oak

Oak trees are native to the northern hemisphere. There are around 600 species of oak, both deciduous and evergreen. Oakwood is remarkably strong, heavy, and durable. It is also resistant to fungal attacks.

Qualities of Wood

Timber is the type of wood used for construction, primarily for structural support such as beams and pillars.

Usually, timber comes from matured trees by cutting them into beams and planks after peeling logs. However, to fulfill its function, timber needs to have certain qualities. Additionally, it needs to be devoid of any defects or imperfections.

- Appearance

- Color

- Durability

- Elasticity

- Fibers

- Fire Resistance

- Hardness

- Shape

- Sound

- Strength

- Toughness

- Water Permeability

- Weight

- Workability

Durability

Freshly cut timber gives off a sweet smell. It also has a shiny appearance. Both these features are signs of high quality.

However, different countries have set timber appearance grades of their own. For example, Australia and New Zealand have three appearance grades: Grade A, B, and C, with A being the best-quality appearance.

The surface of A-grade timber needs to be sanded to a minimum 60 grit finish. On the other hand, Grade B is commonly used in construction, while Grade C is used in packaging and similar applications.

In Nordic timber markets such as Sweden, appearance grading is based on knots, grains, top rupture, fungal attack, deformation, insect damage, discoloration, and dimension deviations, among other things.

The standard for appearance grading of softwoods is SS-EN 1611-1.

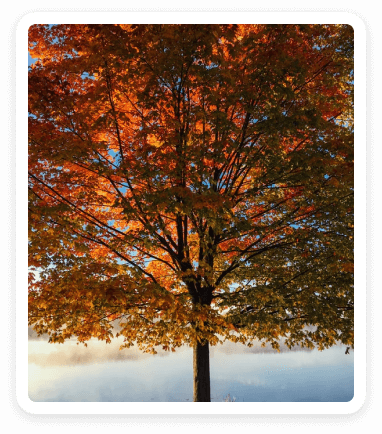

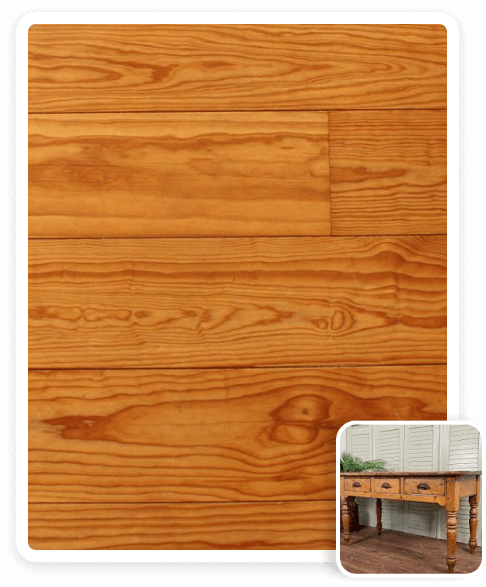

Color:

It should also have a dark color. Light color usually indicates less strength. However, different woods have different colors.

For example, freshly cut hardwood like Walnut will have a dark brown color,

while softwoods such as Deodar and Pine have golden yellow and whitish shades respectively.

Durability

High-quality timber is remarkably durable. It should be resistant to climatic changes, pests such as termites, and fungal attacks.

A few types of wood such as cedar and redwood are naturally resistant to termites. However, resistance is limited to only heartwood and bark.

Usually, pressure-treated timber is more resistant to insect and decay compared to untreated wood. In this process, a preservative gets embedded in the pores of the wood, forming a chemical barrier that can withstand termites and decay.

There are different grades and classes of wood based on their resistance to various environmental factors.

There are 5 classes of natural durability to resistance against wood-destroying fungi.

Class 1 – Very Durable

Class 2 – Durable

Class 3 – Moderately Durable

Class 4 – Slightly Durable

Class 5 – Not Durable

There are two classes of durability against an attack by wood-boring beetles..

Class D – Durable

Class S – Not Durable

There are three classes of durability against an attack by marine organisms.

Class D – Durable

Class M – Moderately durable

Class S – Not durable

Finally, there are three classes of durability against an attack by termites.

Class D – Durable

Class M – Moderately durable

Class S – Not durable

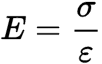

Elasticity

Elasticity is also an important attribute of timber. It allows the wood to regain its original shape with maximum accuracy. This property plays a crucial role in making sports and construction equipment.

E = Young’s modulus, pressure units

σ = uniaxial stress, or uniaxial force per unit surface, pressure units

ε = strain, or proportional deformation (change in length divided by original length), dimensionle

The elasticity and load-carrying capacity of wood are substantially higher in the direction parallel to the grain compared to the perpendicular direction.

That’s why structural (construction) timber is sawn into boards with the long axis of the board aligned parallel to the grain. It provides better dimensional stability or resistance to distortion.

Fibers

The arrangement of the fibers and the orientation of the microfibrils influence various qualities of wood such as elasticity. Usually, hardwood fibers have small lumen diameters and thick cell walls compared to softwoods.

When using as timber, the fibers should be straight, compact, and firm. Wood with twisted fibers possesses little strength as opposed to wood with straight fibers.

Fire Resistance

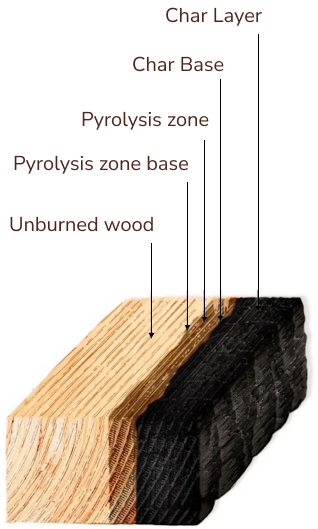

The wood should be resistant to fire. Usually, when timber or wood gets exposed to fire, it goes through a thermal breakdown, during which a layer of charcoal forms on the burning surface.

The layer acts as an insulator providing fire-resistance to the inner core of the wood.

This self-protecting nature of the wood provides the basis for its natural fire-resistance. That’s why denser wood often has higher fire resistance.

Hardness

Hardness is an inherent quality. It will change depending on the species of the wood you choose. In most applications, such as construction, flooring, and sports equipment, the wood needs to withstand deterioration due to mechanical wear and tear and physical abrasion.

The Janka hardness rating system is a universally accepted industry standard to determine the hardness of a timber sample. It runs from zero (softest) to 4,000 lbs (hardest). Brazilian Walnut is one of the hardest woods with a score of 3,684 lbs on the Janka’s Scale.

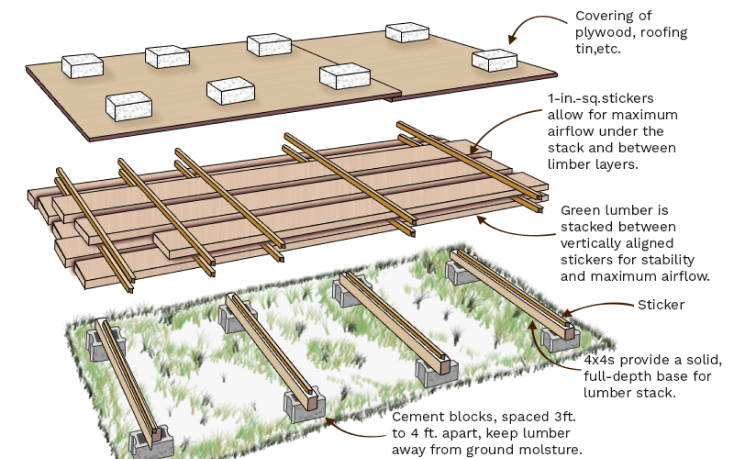

Shape

High-quality timber will always retain its shape and structural integrity during the seasoning or conversion process. Seasoning involves removing moisture from freshly cut wood.

The dried wood is considerably lighter and stronger than un-seasoned wood. It is also easier to finish and less likely to warp or mold.

Sound

When struck, high-quality timber produces a clear ringing. The hollow sound is a sign of low moisture content and high dryness.

A dull heavy sound, on the other hand, is an indication of internal decay or high moisture content. In other words, wet wood produces a dull thud when struck.

Dull thud sound- Web Product

Strength

It should be able to withstand structural loads, especially in construction. Usually, the strength increases with density.

Timber has three types of strengths including bending strength, shearing strength, and tensile strength.

Bending strength & Tensile strength

Shearing strength

The bending strength is as good as the tensile strength in a flawless piece of timber. Shearing strength, on the other hand, is usually 10-15% of its tensile strength in the direction of the grain.

Toughness

It should be able to endure shocks and vibrations. In other words, it is the ability of timber to change its shape.

Usually, woods with narrow annual rings are the toughest. You can bend such wood easily without splitting them up.

Water Permeability

Ideally, water permeability of timber should be zero. However, in reality, using the timber with the lowest water permeability is used. If the wood has higher water permeability, it will quickly absorb moisture, resulting in fast decay.

Water permeability is a critical factor in determining the longevity of timber. Usually, the size of openings connecting the wood cells determines the level of water permeability. As a result, it will change from species to species

Weight

Usually, heavy timbers are the toughest and hardest. However, unseasoned green wood has a higher moisture content which increases its weight.

Thus, only seasoned and heavy timber should be considered for structural end-use.

Workability

Any type of wood with excellent workability is easy to machine, nail, and glue. It also has notable turning, carving, and bending properties. It can also retain the intricately carved shapes and designs without degrading for years.

Usually, woods with high resin content tend to be less workable as they clog the teeth of the saw or any other tools. Spiral, interlocked, or otherwise irregular grain also makes it difficult to work on woods.

Difficult to work on woods.

Janka Wood

Hardness Scale

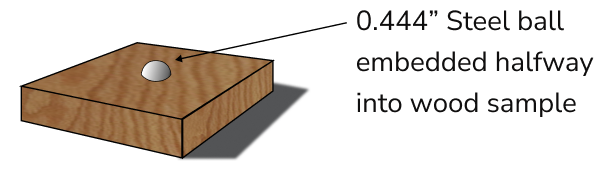

The Janka hardness scale measures the amount of force required to embed a 0.444” steel ball into the wood to the half of its diameter.

A universal wood hardness scale was developed to determine the relative hardness of timber.

You can use the Janka scale to determine the relative hardness of both domestic and exotic wood samples (usually 1” or 2” thickness).

This scale is one of the best ways to measure the ability of the timber to withstand wear and tear. Usually, the higher the Janka scale rating, the harder the wood. The steel ball leaves a hemispherical indentation with an area of 200 mm2 in the wood sample. Different units are used to express the wood hardness scale rating in different countries. In the United States, the measurement is in pounds-force, abbreviated as lbf.

Wood – JANKA HARDNESS (IN LBF)

Wood Processing

Wood has played a foundational role in the construction industry for centuries. However, timber cannot simply be pulled out of the forest and utilized. It must first undergo a transformation phase known as wood processing. The concept of wood processing covers several steps to turn raw wood into usable material.

Once the selected trees in the designated forest area are cut down or felled, they are transported to a sawmill where the wood processing begins. The various stages involved in lumber processing often remain the same.

Limbing and Bucking

The first step is the limbing and log bucking. While limbing is cutting the branches of the felled trees, bucking is cutting the log of a de-limbed tree.

The de-limbed log gets split into predetermined lengths depending on the end use of the timber. These may include saw logs, stud wood, pulpwood, fuel wood, and fence posts, among others.

The specifications for length and diameter for log bucking will also depend on the local marketing conditions. As a fallen tree is under considerable tension, only experienced and skilled buck sawyers should carry out the process of bucking.

Debarking

The next step in timber processing is debarking. It comprises peeling logs with a mechanical force sufficient enough to break the cambium between the bark and the wood.

It is a crucial and delicate process as the quality of debarking will define the cost of the milled timber.

Usually, sawmill owners use a log debarker with sharp-toothed grinding wheels. Sometimes, they can also use a tree debarker with a jet of high-pressure water for peeling logs.

Manual debarking, although possible, is not economically feasible for large volumes as it is labor intensive and time-consuming. The debarking conditions may vary depending on the shape and quality of the timber.

Sawing

Sawing is the most critical part of lumber processing. Usually, a headrig saw is used to cut the log into planks. An optical sensor measures the length and the thickness of each and also identifies visible defects.

It also helps to determine the optimal cutting pattern to get the maximum number of planks from each log.

Smaller logs (diameter less than 2-3 ft) are cut using a series of bandsaws instead of a headrig saw.

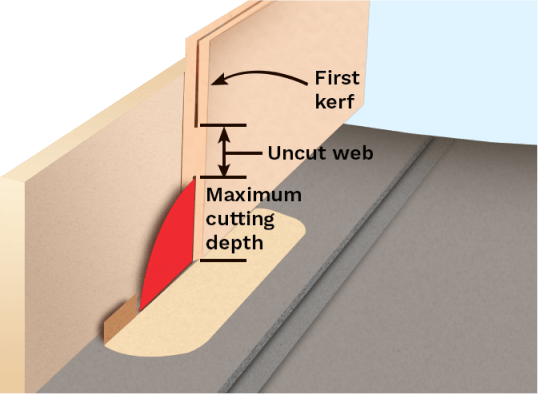

Resawing

During resawing, the large planks are cut into the required widths using bandsaws. The outside edges are also trimmed square.

Drying

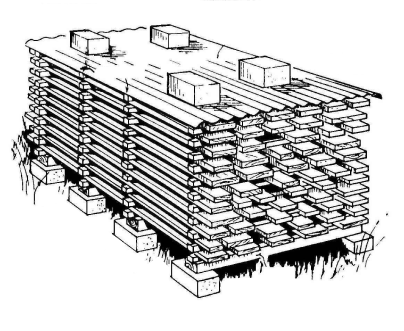

The drying or seasoning of planks is carried out to produce the timber that is durable and resists decay. The wood is either air dried or Kiln-dried. Kiln-dried wood usually has a lower moisture content, compared to the air-dried one.

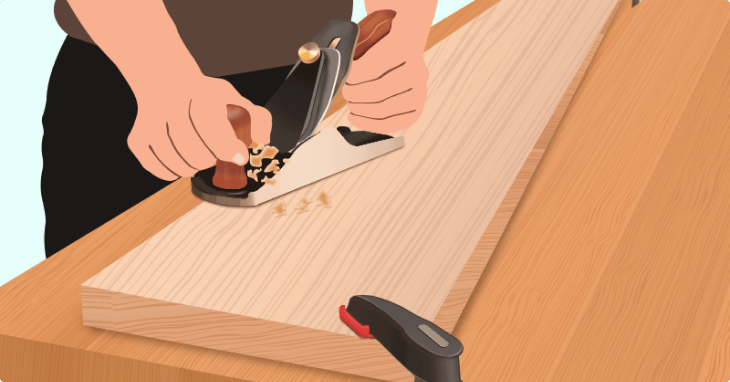

Planing

Planers trim the dried wood planks to smoothen all the surfaces and round the edges.

Quality Check

Despite taking necessary precautions, the finished products may still have some defects.

During the quality check, the final step in the lumber processing, the planks are graded according to number and location of these defects.

This procedure may vary a bit based on the desired outcome. Prior to removing any timber from the forest, there should always be a detailed plan in place for how the wood will be processed and used. In regards to wooden furniture, however, wood processing is only the beginning of the transformation.

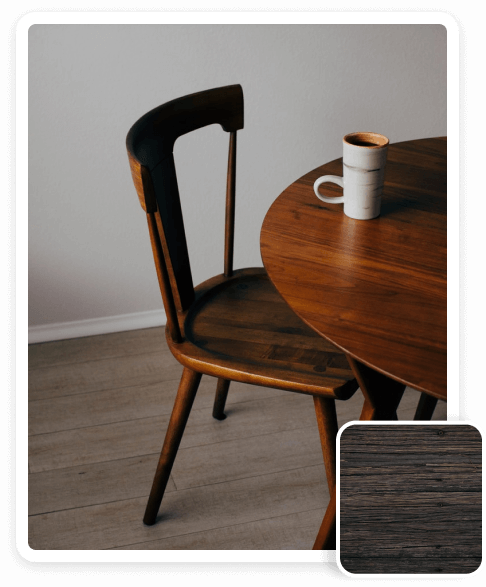

Wood for Furniture

Once the wood is processed, there are several vigorous procedures it must undergo to be converted into furniture. Wood is simply a material waiting to be altered and crafted into a final product. Furniture is the end goal in which the wood has been manipulated and shaped into something that can be proudly displayed. Here are the steps involved in this process.

Limbing and Bucking

Humans have used wood for making furniture for thousands of years. Despite several technical breakthroughs, mankind has not yet found anything as versatile as wood for making furniture. It is also remarkably resilient and requires little maintenance.

Unlike most other materials, such as leather hides, for instance, wood can have multiple lifetimes through refinishing. Thus, wooden furniture offers excellent value for money. It also fosters a sense of natural beauty, looks, and feel. It’s no wonder why wood has remained a popular choice for furniture.

Before we move ahead lets a look some of the interesting numbers.

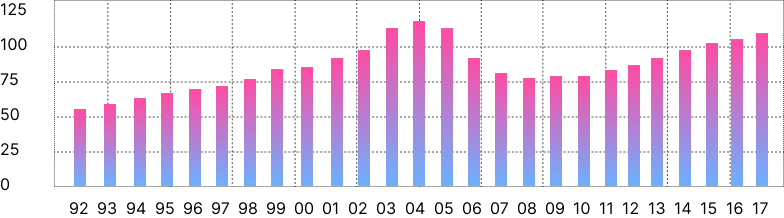

In 2017, furniture and home furnishings store sales amounted to about 113.78 billion U.S. dollars.

Furniture and home furnishings store sales in the United States from 1992 to 2017 (in billion U.s. dollars)

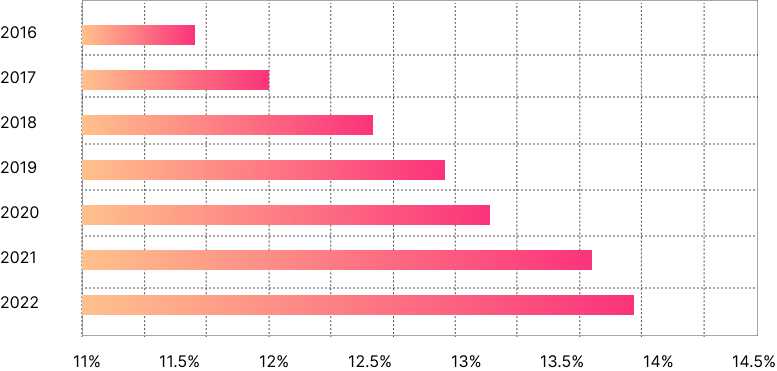

The booming e-commerce industry has also had an influence on the sales of furniture.

Furniture and home furnishings sales as percentage of total retail e-commerce sales in the United States from 2016 to 2022

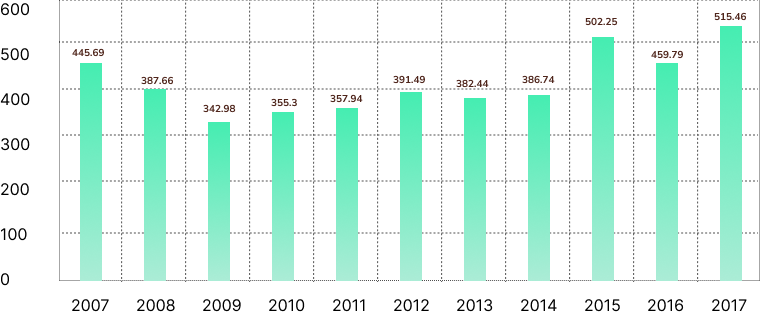

Average annual expenditure on furniture per consumer unit in the United States from 2007 to 2017 (in U.S. dollars)*

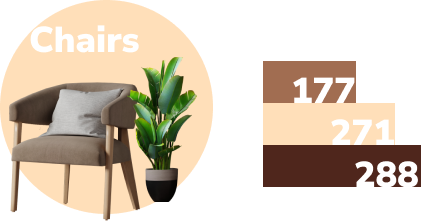

Here is the average price paid by households for selected furniture items in 2016, by generations.

- In 2018, the United States had the largest furniture market with revenue of $304,270.48 million.

- On the other hand, the global furniture market was valued at around $331.21 billion in 2017. It is expected to reach approximately $472.30 billion by 2024, growing at a CAGR of around 5.2% between 2018 and 2024

Whether you are using smart furniture, going for a modern look, or a Victorian decor, wood plays a critical role in furniture making. For example, a recliner, irrespective of how contemporary it seems, will always have a wooden frame.

Only wood can withstand the kind of motion or weight shifting a recliner experiences. Plus, using high-end wood for exposed areas such as arms, back, and feet, renders a classic look. The bottom line is people will continue to use the best wood for furniture as long as it is available.

From Wood to

Furniture

Although you can use different types of wood for furniture, it will still need to go through a series of processes before it turns into a beautiful piece. The furniture making process can change depending on the desired end-product. But, a few steps are universal.

Splicing and Cutting

First, the woodworking lumber needs to be cut and spliced into desired parts of a product. Carpenters use a variety of tools for this purpose. Only the best wood for furniture is cut and spliced.

Molding

Spliced and cut timber is then molded to achieve the desired shapes and sizes.

Planing and Drilling

Sometimes the wood needs to be drilled using either handheld or machine drills. Care is taken not to split the wood while drilling to avoid damage and wastage. The pieces are then sent to a planning machine to get a smooth surface without a line saw.

Sanding

Before the assembly, all the components are carefully sanded to round sharp edges and smoothen out surfaces.

Assembling

At this stage, each component of the furniture is assembled to create the desired end-product. Joints are glued together with powerful adhesive.

Finishing

The purpose of finishing is to bring out the aesthetic features of the wood. Usually, several coats of wax, shellac, drying oil, lacquer, varnish, or paint are applied using machines. This can also be done by hand.

Packing

The end product is finally packed and shipped to the desired destination.

What Type of Wood

is Best for Your

Furniture?

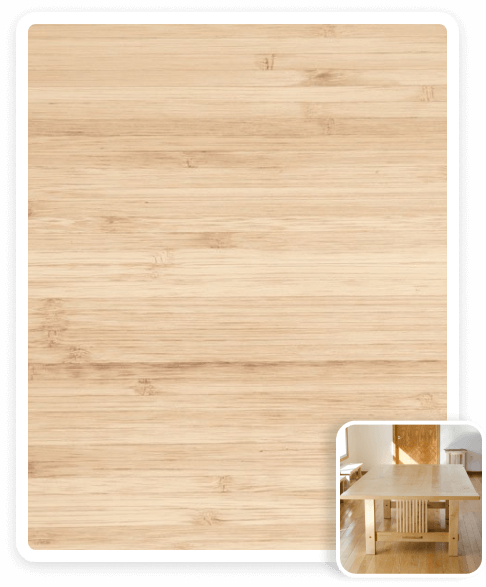

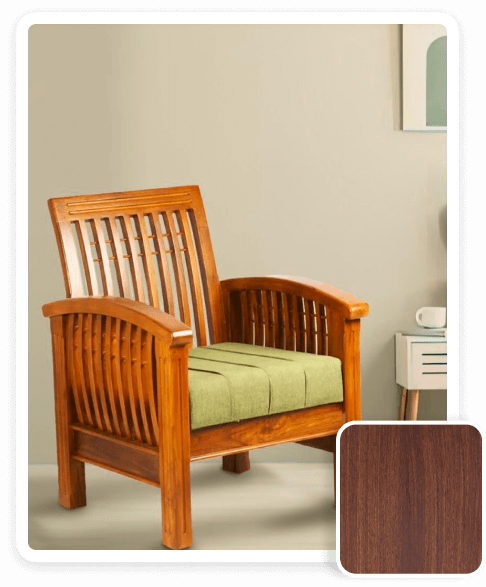

Almost any type of wood can be used to make furniture. However, the quality and market value of the unit will depend on the different types of wood, as well as the uses and features. But, which is the best wood for furniture?

The answer will depend on a variety of factors including cost, durability, color, your space, what you want to build, etc. It is also essential to know where to buy wood for furniture making that suits your budget and needs.

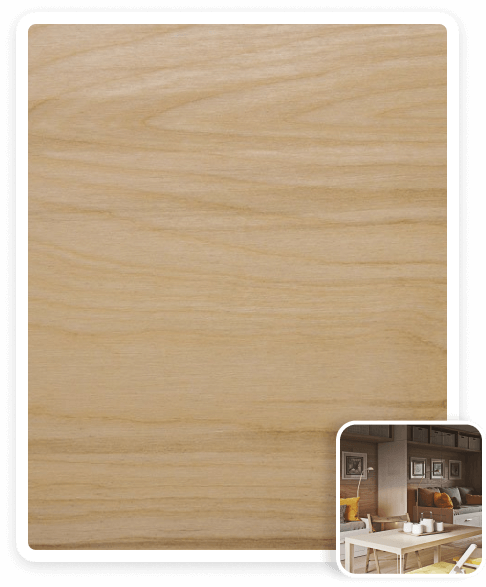

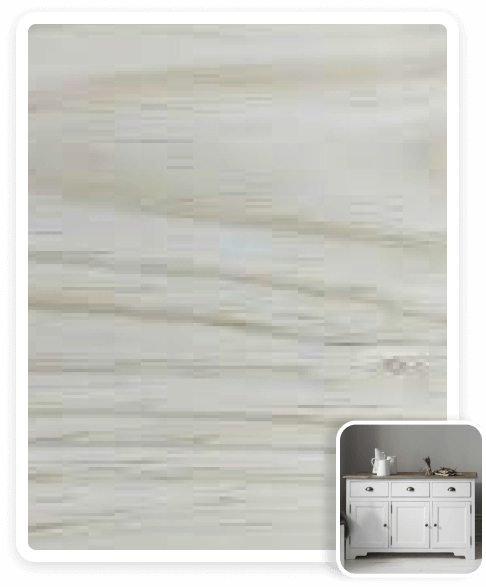

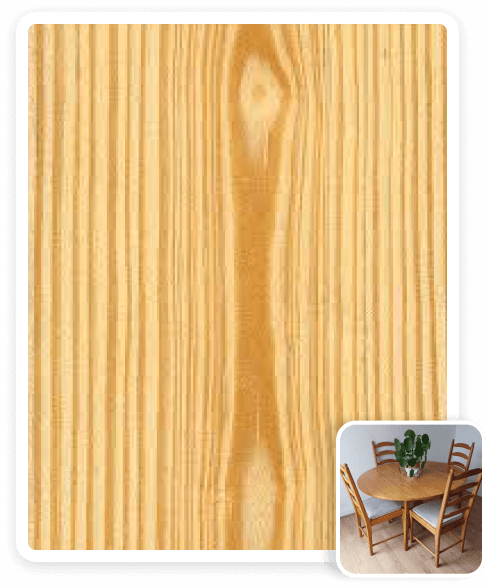

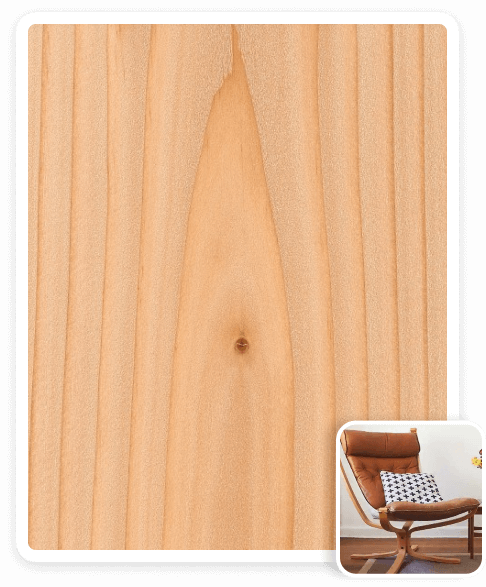

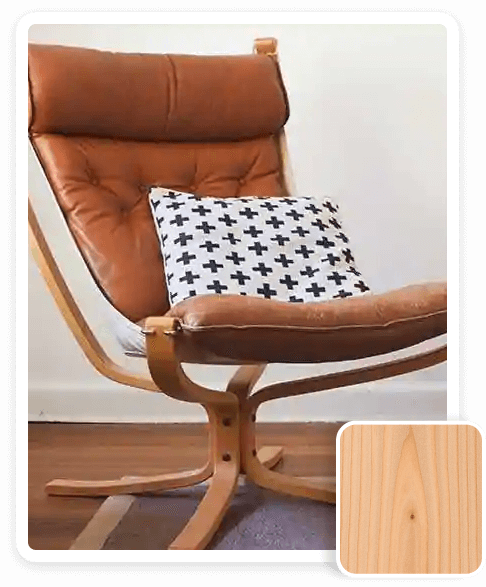

Pine is inexpensive, lightweight, and readily workable. It is often used to make rustic furniture pieces. However, it is prone to scratches and dents.

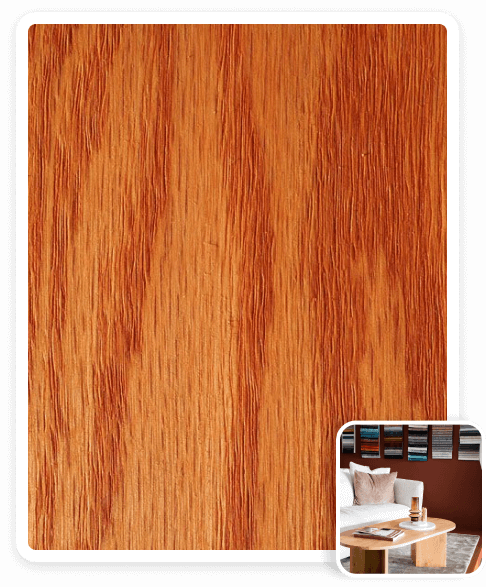

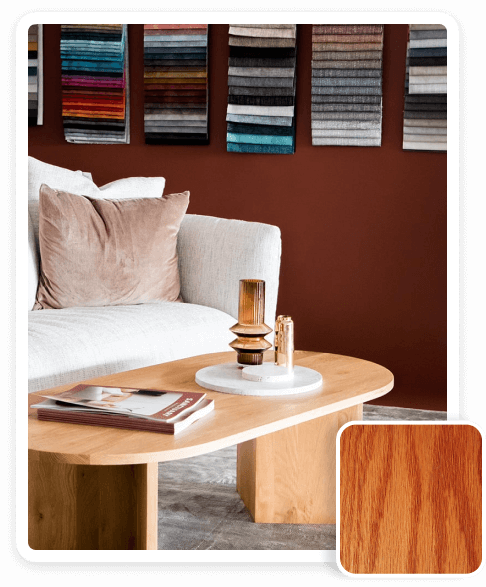

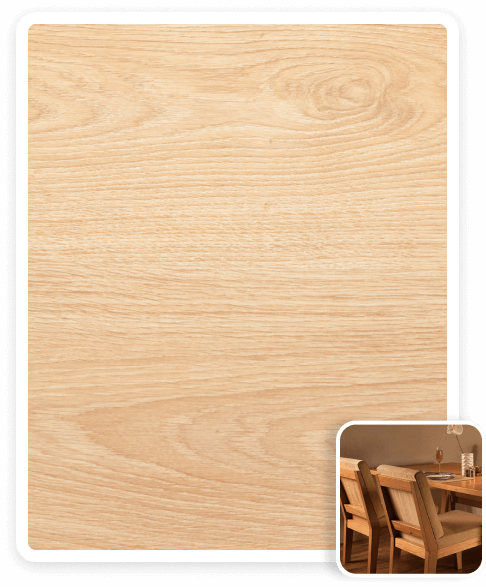

White oak is beautiful, heavy, durable, and suitable for cabinetry and kitchen furniture. It has a distinctive look when finished. It is also resistant to warping.

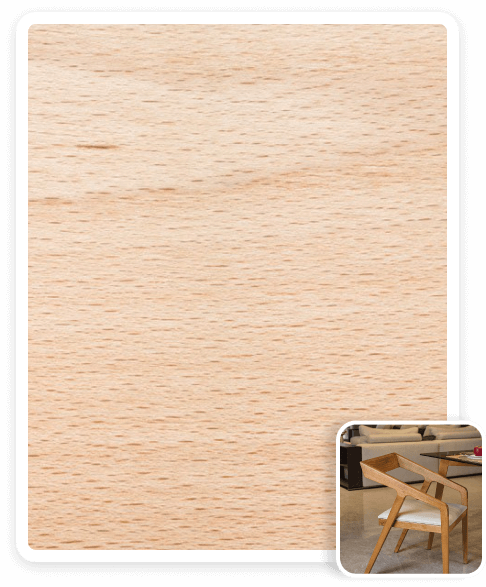

Being one of the hardest, Maplewood is suitable for heavy-use items such as dressers and kitchen cabinets. It can be stained to mimic an expensive wood.

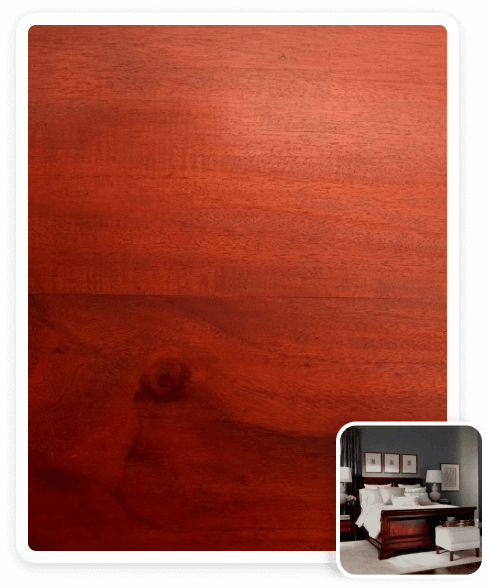

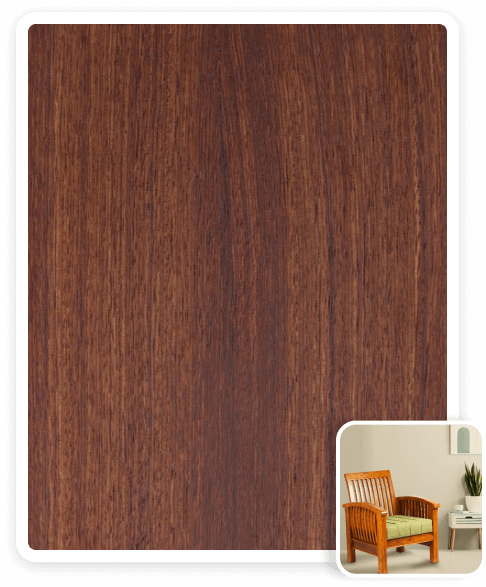

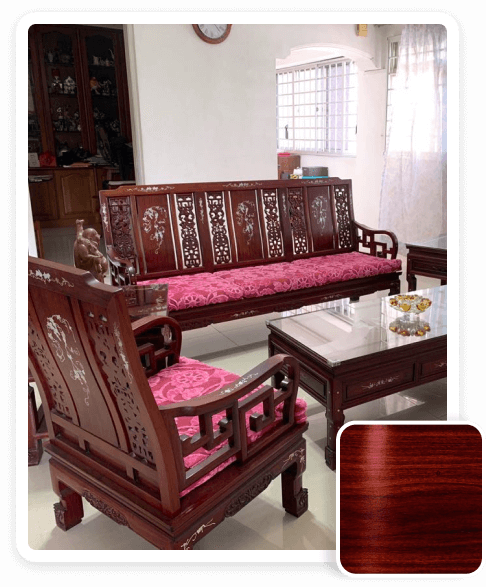

Walnut is extremely beautiful. It can withstand very intricate carving. That’s why it is often used to make headboards, ornate antique-style dining tables, and mantels. Oil finish is more than enough to bring out its natural color.

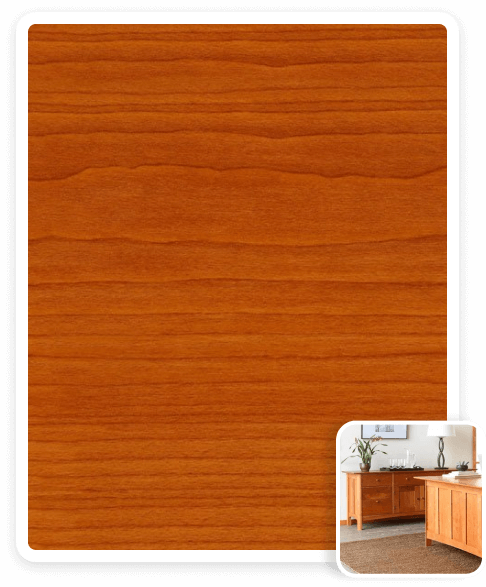

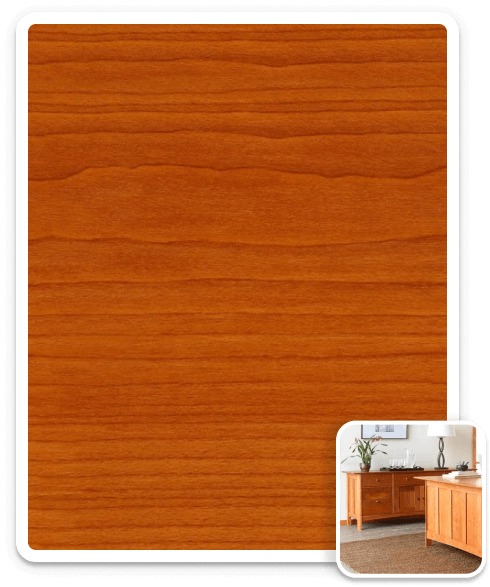

Cherrywood is probably the best wood for indoor pieces of furniture, such as carved chairs and tables. It is highly durable and resistant to decay and abrasions. It is an all-around great wood. However, it is expensive.

How to Identify

the Ideal Wood for

Furniture

The forests of the world are chock full of different wood types. There is a huge array of materials out there that can be used to create practical, durable, and exotic furniture. Each has its own unique qualities and purpose in the construction process. However, some are more ideal than others.

Unfortunately, timber suppliers do not always label the materials they carry. That being said, you should have a good idea for how to properly identify the right woods. The extensive range of treatments can make it challenging to distinguish certain types or species.

When selecting wood for furniture, here are some tips to get you started.

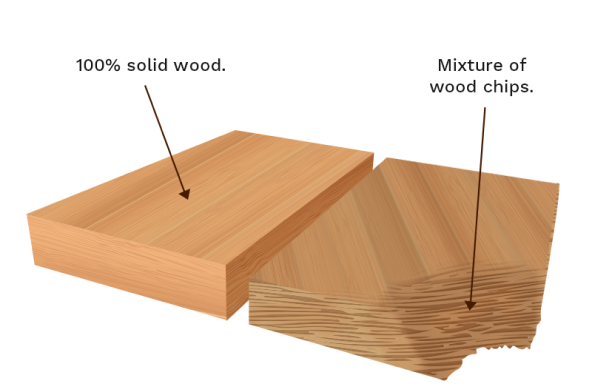

Make Sure It Is Solid Wood

- First, look at the edges of the wood piece to see the end grain. If you see growth rings that match up with the direction of the grain along the face of the wood, you are looking at actual solid wood.

- If the same pattern repeats itself on all sides of the board, it may be a veneer.

- Sometimes, a piece of particle board, or MDF, is covered with a thin layer of plastic, stained, or painted to make it look like the real wood. In such case, you can use a planer or sander to reveal the real nature of the wood.

- At times a solid looking wood may not be even fully solid and made up of wood chips.

Check the End Grain Color

- The end grain color plays a crucial role in wood identification. Once again, you can sand or plane the ends to find out if the color is natural or artificial.

However, you should remember that wood tends to darken with age. Even inner wood takes on a patina as it ages.

Examine the End Grain Pattern

- Examine the End Grain Pattern

- Hardwood usually has an open pore structure while softwood has a smooth texture with no grain indentations.

- Some woods also show distinct grain patterns when quarter sawn or plain sawn. Some of the woods also have characteristic grain patterns such as straight, knotty, or interlocking. So, you need to ask yourself the following.

1. Is the grain texture open or porous?

2. Is it quarter sawn or plain sawn?

3.What is the pattern? Is it curly, knotty, or interlocking?

Find out If It Is Weathered or Stained

- Rustic and naturally weathered wood can add a great feel to your interior. However, weathering the timber in natural wind, sun, and rain takes a lot of time. So, many people add a weathered gray finish on a piece of wood.

- You can visually inspect the piece of wood to determine if it is weathered or stained. Usually, naturally weathered woods take on a blue or grayish color. If the color looks uneven or there is varnish on it, it is most certainly is stained, not weathered.

- However, visual inspection is not always easy or accurate. In such a case, you will need to send a sample to the nearest laboratory for microscopic evaluation.

Look at the Hardness and Weight

- You can use your hands to get a feel for the weight and hardness of the wood sample. Simply scratching the wood can give you an idea for how hard it is.

- Compare these qualities with the weight and hardness of other species in the wood database. Heavy woods often tend to be hard.

- Alternatively, you can measure the length, width, and thickness of the wood to determine its density. Be sure to compare it to others in the database.

Find out the Origin of the Wood

- The more you know about the original source, the easier it becomes to identify different woods. For instance, if the wood was salvaged from a boat, it is more likely to be free of knots. This scenario would typically involve woods like ash, cedar, or oak.

- Knowing how large the timber is can also help identify wood, as some trees tend to have small barks.

- Similarly, knowing the intended use of the wood can also help to identify it. For example, swamp ash is often used to make guitar bodies.

- Knowing how old the wood is can also help in this process. Alder was used extensively in the 1950s and 1960s to make guitars.

Search for a Peculiar Characteristic

- In addition to the above qualities, some of the woods possess distinct characteristics like odor and fluorescence. You can use these properties for wood identification.

- Woodworkers have also developed chemical tests for identifying wood. Usually, a water-soluble reagent is used to distinguish different species.

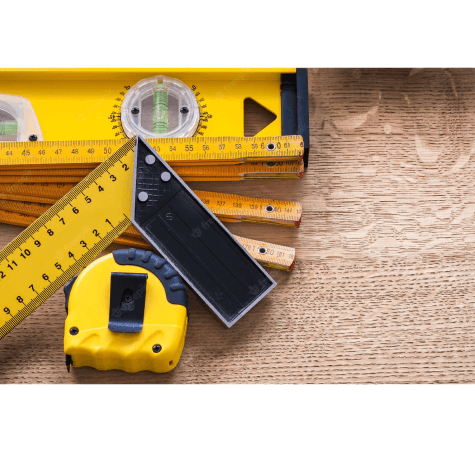

Which Tools Will You Need for Wood Identification?

For wood identification, you will need a measuring tape, a small block planer or a very sharp knife, a magnifier, and of course, some practice and experience.

Woodworking Tools

Buying readymade furniture is fun, but making your own (DIY furniture) is even more fun. So, what do you need to build your own study table? Besides honing your carpentry skills, you will need to know about basic woodworking tools. What types of tools should you invest in?

From simple hand tools to power tools, there is a wide range of carpenter gadgets out there. Some will see more use than others. Let’s discuss some of the essentials.

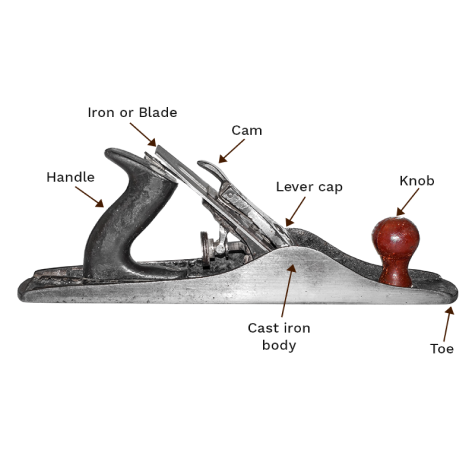

Block Plane

It is one of the compact and versatile carpenter tools that go back to Roman times. It can be used to tackle end grain cuts, level corner joints, smoothen away the machine marks and easing of sharp edges on furniture components.

Chisel and Mallet

A chisel is also a hand tool often used for cutting or carving wood. There is a wide range of woodworking chisels meant for carving, framing, cornering, paring, skewing, mortising, bevel edging, and butting. Chisels are almost always used with a wooden mallet.

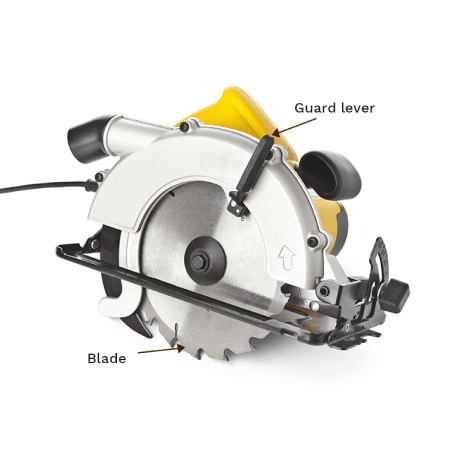

Circular Saw

A circular saw is a power-saw. The circular blade with sharp teeth will make smoother cuts. It is ideal for cutting all types of plywood, sheetrock, and framing materials. However, it only makes straight lines and miter cuts.

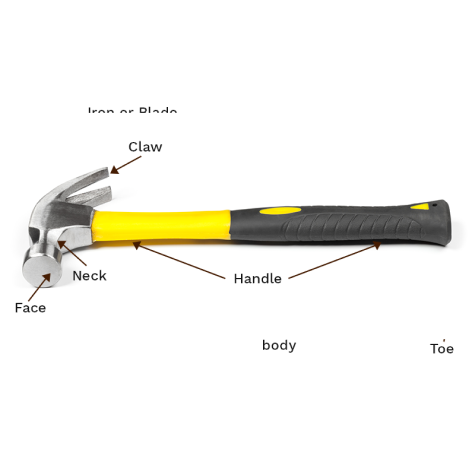

Claw Hammer

In the woodwork, a claw hammer is often used to drive nails and fit parts. The claw is used for pulling out nails. The most commonly purchased claw hammer is the 20 oz.

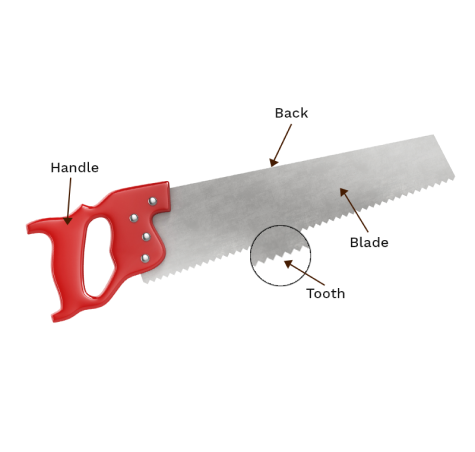

Hand Saw

Hand saws are often used to make the cuts that power saws can’t. There is a wide variety of hand saws including back saw, bow saw, crosscut saw, hacksaw, Japanese saw, pruning saw, and keyhole saw. A hand saw can make circular cuts if needed.

Jigsaw

A jigsaw is used for cutting smooth curves and intricate shapes. It works much faster than a hacksaw or handsaw, saving you a lot of time and energy. The blade operates in an up-and-down motion at high speeds.

Jointer

The jointer smooths the wooden surfaces that won’t go through your surface planer. It can also flatten edges. Thus, it helps you to salvage bowed or warped timber, which is cheap to buy.

Power Drill

A power drill is a must-have on your woodworking tools list. Corded drills are less expensive and can be more versatile than a cordless drill. Most power drills come with variable speeds.

Random Orbital Sander

This tool is the quickest and easiest way to sand wood. The disk moves in random orbits, resulting in ultra-smooth sanding. The design also allows you to sand in any direction.

Router and Router Bits

You will need a router and appropriate router bits to hollow out an area or shape the edges of the wood. You can either buy a hand router or a power router according to your budget and woodwork requirements.

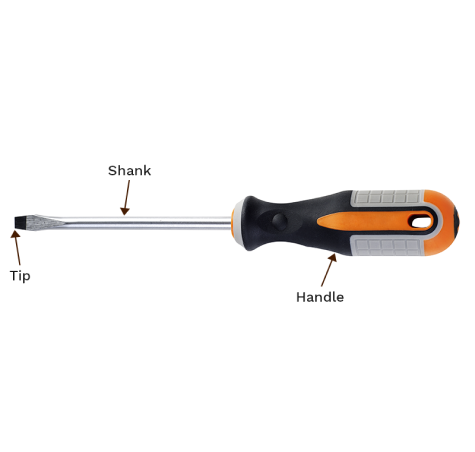

Screwdrivers

When doing any sort of woodworking, you will need many different types of screwdrivers. These categories include ratcheting, cabinet, star drivers, Phillips head, flathead, and small and medium slot screwdrivers. Make sure they are intended for heavy-duty woodworking.

Smoothing Plane

The smoothing plane is a hand-tool that dates back hundreds of years, like the block plane. A well-tuned smoothing plane can impart a glasslike finish to your woodwork.

Square and Tape Measure

Measuring is a fundamental part of woodworking. You will need a measuring tape, framing square, try square, combination square, sliding T-bevel, and a ruler. Don’t forget to buy marking pencils, a knife, and an awl as well.

Thickness Planer

A thickness planer allows you to give a wooden board consistent thickness and smooth both surfaces. Though expensive compared to hand tools, a thickness planer is worth the cost, as it produces a flat surface in a single pass.

Workbench

You’ll need a workbench to make woodworking tasks easier. It should be sturdy and heavy enough to remain still while you are working on the wood. There are many varieties of workbenches.

Parting Words

Whether you are a woodworking enthusiast or just looking for wooden furniture, knowing about the different types of woods and their characteristics can help you make more informed decisions. Hopefully, this guide will help you answer questions such as “Which is the best wood for flooring?” or “Which is the most expensive wood?” or “Which woodworking tools do I need for DIY furniture projects?”

If you still have questions, feel free to share them with us. We will get back to you as soon as possible.